Sandy Shore Farms, a family-run enterprise established in 1956, stands as a prime example of agricultural innovation rooted in tradition. Operating in Norfolk, Ontario, the farm capitalizes on the region's rich, fertile sandy soil to cultivate a significant volume of high-quality produce, including fresh asparagus, onions and bell peppers.

More than just growers, Sandy Shore Farms has adopted a strategy of vertical integration, managing the entire lifecycle of their products, from field harvest to specialized processing, packing, and shipping. This dedication to quality is formalized by their SQF certification, which attests to their adherence to rigorous worldwide food safety standards.

However, managing such a complex, end-to-end supply chain demands more than traditional methods. The continuous need for compliance verification and meticulous record-keeping inevitably generates significant administrative overhead, often referred to as 'audit fatigue'.

Sandy Shore’s primary challenge was transitioning their commitment to an "unbreakable supply chain" into a unified, digital system that could handle their operational complexities while guaranteeing compliance and efficiency. To help achieve this level of operational excellence, Sandy Shore Farms partnered with Croptracker.

From field to finished product

Sandy Shore Farms is vertically integrated, meaning the farm acts simultaneously as a fresh produce packer and a specialized food processor, transforming raw crops into value-added products like Fresh Whole Peeled and Diced Spanish Onion and Cored Bell Peppers.

This integration results in distinct operational pathways, or workflows, that must be tracked within a single platform:

- Fresh packed produce

- Value added produce

- Onions and peppers, which require processing steps like peeling or de-coring, are tracked through Croptracker’s Packing/Processing module against a specific customer’s request.

For the onions and peppers harvested on Sandy Shore’s own farm, and for onions and peppers they receive from nearby farms for processing and packing, inventory is created using the Receiving module mobile app. Workers are quickly able to log the total amounts, time it was harvested and received, where it was harvested from and assign it a Traceability Lot Code (TLC).

For asparagus harvest, Sandy Shore uses Croptracker’s Pre-Print Harvest workflow to support quickly logging multiple pieces of harvest inventory against the employee who picked it. Pickers are sent out to harvest with labelled reusable lugs and when the stack is full and ready to be moved from the field, a supervisor uses the Croptracker app to scan the tags against the employee, generating employee linked inventory records. The total time of the harvest, the total harvest yield and how productive each picker was is captured in one step.

Sandy Shore manages both the fresh and value added products order fulfillment using the Order Desk module. Sales orders are created based on incoming purchase orders, providing the digital anchor for the entire downstream packhouse workflow. This ensures that labor, inventory consumption, and final packaging are all precisely targeted to fulfill specific customer demands.

When raw inventory is converted into a finished product (e.g., whole onions from the field into packaged peeled onions or coring and slicing bell peppers), the Packing/Processing workflow prompts the user to record the raw inventory input consumed before proceeding to create products and generate pallet tags for the value added products.

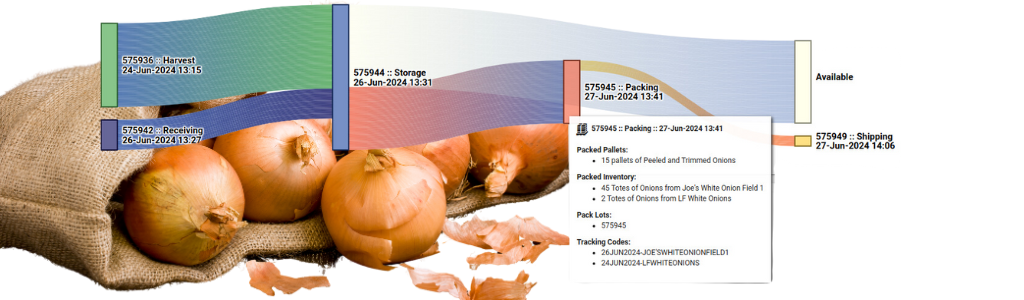

Through this process, Sandy Shore ensures all required traceability records are formatted to meet industry standards. Using Croptracker’s inventory management modules logs a Critical Tracking Event (CTE) and generates a new TLC, linking the finished goods back to the originating raw materials.

Traceability reporting and audit readiness

For an SQF-certified operation like Sandy Shore Farms, maintaining impeccable records and demonstrating rapid recall readiness is non-negotiable. This intense requirement for verification often consumes excessive administrative resources.

Croptracker addresses this administrative burden directly with its advanced reporting suite, centered on the Mock Recall Report, and the Receiving Traceability Report. This feature is critical for converting the time-consuming compliance process into a high-speed, automated function. By entering a finished product Lot Code (TLC), the system instantly generates a comprehensive report tracing the product's entire lifecycle, including where it came from and where it ended up.

This report documents every Critical Tracking Event (CTE) in the product’s path, tracing back through the packing event, the exact receiving date, and all the way to the original growing block and the specific employee responsible for handling the raw or finished goods. The ability to generate this full-lifecycle report in moments, instead of days of manual spreadsheet reconciliation, is key to meeting compliance standards and drastically reduces internal audit time. The platform serves as the secure repository for all records, which must be retained for at least two years.

This automated traceability serves not only as a safeguard against risk but also as a market differentiator. It provides buyers with a powerful confirmation of supply chain transparency. If an incident requires action, the detailed report identifies the specific raw inventory lot, the date of processing, and the product grade/status, allowing for highly targeted responses that protect the Sandy Shore brand and minimize potential financial losses from mass recalls.

Comprehensive quality control

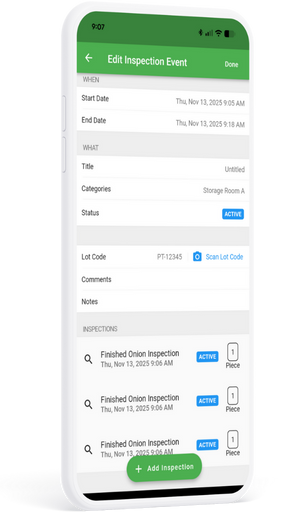

Sandy Shore Farms’ commitment to quality is upheld through the structured application of the Quality Control (QC) Module at two critical points in their workflow. Sandy Shore’s expert Quality Control and management teams worked with Croptracker’s onboarding and support to initially digitize their collection templates in Croptracker, and they have been refined by Sandy Shore’s team as they are used. By embedding these checks directly into the digital process, they ensure consistency and create a robust, auditable quality history.

Stage 1: Preventative input QC

Inspections are recorded immediately upon receiving raw materials, using custom templates such as the Raw Onion Inspection and Raw Pepper Inspection. This preventative measure ensures that the quality of inputs meets standards before they move into the high-cost processing stage. QC staff use the mobile application to complete inspection templates against the scanned inventory tag, immediately linking the quality results to the raw material’s Lot Code.

Stage 2: Final output QC

After the processing and packing steps are complete, a final quality check is performed against the finished goods, using a Product Inspection workflow. This guarantees the output meets buyer specifications and internal quality benchmarks.

The digitization of the QC process ensures consistency, removing the subjectivity inherent in paper-based scoring systems. By tying QC results directly to the Lot Code, the system ensures data integrity, allowing managers to efficiently block or redirect inventory that fails inspection, drastically reducing the risk of quality complaints down the supply chain. Management uses the Product Inspection Report and Inventory Inspection Report to view summarized inspection results for compliance documentation and ongoing process improvement analysis.

Precision labor management and payroll optimization

Managing a large workforce, including hundreds of seasonal and migrant employees, across varied activities such as Harvest, Packing, and Grading, requires a precise and auditable timekeeping solution.

Sandy Shore utilizes the Punch Clock module to track activity. Supervisors use the mobile application to rapidly punch in employees or entire work crews against specific Activities (harvesting, cutting/dicing, clearing etc.) and Blocks (locations). In the packhouse, the Kiosk option enables employees to self-scan badges for quick clock-ins with pre-selected default work locations and activities, ensuring accurate time tracking starts the moment work begins.

Using the Punch Clock module manages time logging, breaks, and generates the necessary raw data in the formats like the Employee Worklog Report. Crucially, the platform features a Payroll Report, which acts as a technological bridge, formatting the time data precisely for integration with Sandy Shore’s Sage accounting software.

This degree of automation delivers substantial financial returns. By providing payroll-ready data, Sandy Shore significantly minimizes the manual administrative burden that typically plagues farm bookkeeping—a pain point that can cost farm operations many hours (or days) of work each payroll cycle.

Beyond simple time tracking, the accurate data linked to specific activities and locations allows managers to conduct detailed labor efficiency analysis. This enables strategic deployment of work crews, helping managers identify where time is spent most effectively and ultimately driving measurable cost savings across the operation.

Cultivating the future of farm technology

Sandy Shore Farms exemplifies how advanced agricultural technology can be leveraged to manage the complexities of modern, vertically integrated food processing. The partnership with Croptracker provides the essential infrastructure to support their mission of maintaining an innovative, and sustainable operation.

For Sandy Shore Farms, traceability isn't just a regulatory checkbox - it's a promise to our customers. With Croptracker, we can generate comprehensive traceability reports in moments, instantly tracing a product back to its origin. That time saving allows us to focus our resources on what really matters: cultivating high-quality crops and meeting our customers’ needs.

The implementation of Croptracker’s full suite delivers three core operational advantages:

The rapid generation of the Mock Recall Report ensures audit readiness and provides the precise data required to protect brand integrity in the event of an incident.

Operational visibility:

The seamless flow of data from Receiving through Packing and QC, tied to the Order Desk, gives managers real-time status on inventory availability and production throughput.

Administrative efficiency:

By integrating technology to simplify complex compliance and administrative tasks, Sandy Shore Farms is setting a standard for responsible stewardship and operational excellence, ensuring their business success endures for generations to come.

Croptracker is eager to continue working with Sandy Shore to optimize our workflows and features to better support fresh produce Growers, Processors and Packers. If you would like to learn more about how Croptracker can support better traceability, visibility and efficiency at your fresh produce operation, find a time on our live demo booking calendar here.

For Sandy Shore Farms, traceability isn't just a regulatory checkbox - it's a promise to our customers. With Croptracker, we can generate comprehensive traceability reports in moments, instantly tracing a product back to its origin. That time saving allows us to focus our resources on what really matters: cultivating high-quality crops and meeting our customers’ needs.