For most fresh produce growers right now, the pressure to protect already slim profit margins is high. In apples in particular, overproduction and staggering labour costs mean that no path to revenue protection can be ignored. One of the avenues our growers are increasingly headed down to help secure their profit is closer picker quality management.

With the risks of improperly handled harvest so high, the time spent training, monitoring and correcting picker performance is worth it. In this use case article, we will detail the why and how of defect monitoring at harvest for better post harvest management, higher pack-out rates and ultimately more return to the grower.

Higher production costs than profit

In the last few decades, apple growers have significantly enhanced production with increased planting density, optimized varietal development and precision orchard management technologies. Globally, apple production has reached ~82 million metric tons annually, a very close match to the global consumption, however this figure hides some nuance about profitability. The apple production rate above refers to the apples that actually hit the market, and includes apples that went for processing, not making the cut for more profitable fresh market retail. It is also not reflective of all apples grown each season due to the unharvested fruit left in the orchard.

The table below shows the approximate average percentage of apples that make it to retail as fresh apples; are headed for processing into juice etc; or are left unharvested in the orchard. Note, these figures are more indicative of the Washington average rates as they are the largest producer in the country. Michigan and New York, the next biggest apple producing states generally have a higher percentage of apples headed to processing due to climate, varietal and planting/production differences.

Average pack-out rates by variety

| Variety | Average Fresh Pack-out (Retail) | Average Culling Rate (Processing) | Average Unharvested (Abandoned) |

|---|---|---|---|

| Honeycrisp | 55-60% | 30-40% | 5-10% |

| Gala | 80-85% | 12-15% | 3-8% |

| Cosmic Crisp | 85-90% | 8-12% | 2% |

| Fuji | 75-80% | 15-20% | 5% |

| Red Delicious | 70-75% | 20-25% | 5-10% |

| Granny Smith | 80-85% | 12-15% | 3-5% |

For varieties like Red Delicious or Gala, if an orchard block has small fruit or poor color, the grower may leave it on the tree because the picking and packing costs exceed the market value. You can see the reasons for this illustrated in the other tables below.

This second table shows the approximate peak prices paid to the pack house for packed out apples vs processed apples in USD. As is evident, the price for apples that make it down the pack line into a case is much higher.

Packed prices vs. Processing FOB prices by variety

| Variety | Approximate Peak FOB* 40/lb Extra Fancy Case Price | Peak Packed Price per Pound | Approximate Peak FOB* price per Ton for Processing | Peak Processing Price per Pound |

|---|---|---|---|---|

| Honeycrisp | $50 | $1.25 /lb | $180 /Ton | $0.09 /lb |

| Gala | $32 | $0.80 /lb | $150 /Ton | $0.08 /lb |

| Cosmic Crisp | $35 | $0.88 /lb | $160 /Ton | $0.08 /lb |

| Fuji | $32 | $0.80 /lb | $130 /Ton | $0.07 /lb |

| Red Delicious | $26 | $0.65 /lb | $90 /Ton | $0.05 /lb |

| Granny Smith | $28 | $1.25 /lb | $110 /Ton | $0.06 /lb |

*FOB = In agriculture and shipping, FOB (Free On Board) is the price a packing house receives for fruit, excluding shipping costs. This standard metric allows buyers to compare the true market value of the produce itself, regardless of the distance it travels.

When the premium packed price vs. processing price is compared to the cost of production vs. grower returns by bin it quickly becomes clear that margins are slim if not negative and the pressure to ensure a high pack out rate per bin is the only way to ensure profit or even break-even.

Average grower returns and profit margins by variety

| Variety | Average cost of production per Bin | Average grower return per Bin | Net Profit/Loss (per bin) |

|---|---|---|---|

| Honeycrisp | $510 /Bin | $550 /Bin | +$40 |

| Gala | $265 /Bin | $305 /Bin | -$40 |

| Cosmic Crisp | $485 /Bin | $405 /Bin | +$80 |

| Fuji | $240 /Bin | $315 /Bin | -$75 |

| Red Delicious | $165 /Bin | $255 /Bin | -$90 |

| Granny Smith | $245 /Bin | $290 /Bin | -$45 |

It is this reality that demands growers minimize damage to harvested fruit as much as possible in order maximize the pack out rate. This can mean making the decision to leave more fruit unharvested because the costs of picking processed fruit is negating any returns. High labor costs creates a zero-sum game where every apple that is bruised or punctured during harvest represents a total loss of the high-cost labor invested in its picking. When roughly 99% of production costs can be attributed to labor, ensuring pickers are skilled enough to pick for premium packed quality is essential.

Consequences of picker defects

Before we get into how to minimize defects with pick monitoring, we will briefly outline the consequences of specific picker defects.

Poor grade picking

Pickers should be trained to recognize what would qualify as a high grade apple, one that makes it down the packline to a case. Bins with high pack out rates will contain apples that have high color and are not too large, small or misshapen and don’t have visible growing defects. When too many under color and too small apples make it in the bin, the pack % rate can quickly fall below break-even payment returns.

Bruising and punctures

Monitoring picker quality is not merely about aesthetic grade standards. Apples are living organisms and any to their skin and tissue will speed up senescence and decay.

Bruising is damage to fruit tissue caused by external force without skin rupture. This damage is often initially invisible, only manifesting as brown lesions several hours after the impact. Bruising significantly increases the production of ethylene and boosts the respiration rate. Bruising susceptibility increases as fruit matures.

Punctures and skin breaks represent a more immediate threat than bruising, as they provide an unimpeded pathway for opportunistic pathogens. Stem punctures occur when an apple's stem, or the stem of a neighboring fruit, cuts the skin. Stem tears or stem pulls occur when a picker pulls the fruit away from the tree rather than using the recommended twisting motion, resulting in an opening in the stem bowl that is highly susceptible to rot.

Both bruising and stem punctures can lead to more significant losses when they are left in the bin during storage. As apples can be kept in storage for up to 12 months (depending on the variety), harvest defects act as catalyst for storage disease that can devastate inventory beyond the few apples initially damaged.

Tree damage

Not all picker defects are about the current harvest. Pickers can also inadvertently hurt future yields by damaging the tree during picking. When the stem end is pulled from the tree too roughly and takes some of the tree with it, it can result in no flowering and fruiting on that branch end the following year. Particularly in precision managed, high density orchards, where most fruit left on the tree after pruning is intended for fresh packing, too much of this can significantly reduce next season’s yields.

Picker defect monitoring in Croptracker

Growers implementing picker defect management workflows with Croptracker will use the Harvest, Punch Clock and Quality Control modules primarily. Some users boost the process with our computer vision modules, Starch Quality Vision™ and Harvest Quality Vision™.

Harvest timing planning

To maximize pack-out rates, harvest must begin at the precise intersection of fruit maturity and shelf-life stability, commonly determined by monitory growth, coloration and starch development leading to harvest. Growers use Starch Quality Vision™ to create a sharable digital SPI record and to help eliminate the subjectivity of traditional starch-iodine testing. By capturing images of sliced fruit via the mobile app, Croptracker’s AI instantly calculates the starch index, allowing managers to monitor the conversion of starch to sugar in real-time.

Coupling these insights with historic Harvest records enables growers to predict the ideal window for each block. Timing is critical: harvesting too late increases susceptibility to bruising and internal breakdown, while harvesting too early results in fruit that fails to meet the size, color, and flavor profiles required for premium retail cases. By hitting this narrow window, growers ensure the fruit is resilient enough to withstand the physical demands of picking and long-term storage.

Picker training and crew optimizing

Preparation for a high-quality harvest begins long before the first bin is filled. Using the Punch Clock, Harvest and Quality Control module reports from previous seasons, managers can review historical performance data to identify high-performing crews and individuals who have consistently maintained low defect rates. This data allows for strategic labor distribution, for example, assigning the most meticulous and skilled pickers to high-value, high-risk varieties like Honeycrisp, where the margin for error is slimmest or distributing skilled returning pickers throughout your harvest crews so they can lead newer pickers by example.

Before the season starts, Croptracker can also act as a central record for training materials. Managers can review past Inventory Inspections, including photos of common defects like stem punctures from previous years, to show pickers exactly what to avoid in their specific orchard environment. By combining these visual guides with physical color cards and growing defect guides, crew leads can set clear expectations. Documenting this training within the employee record ensures that every worker is aligned with the grade standards required to hit break-even targets.

Bin checks at harvest

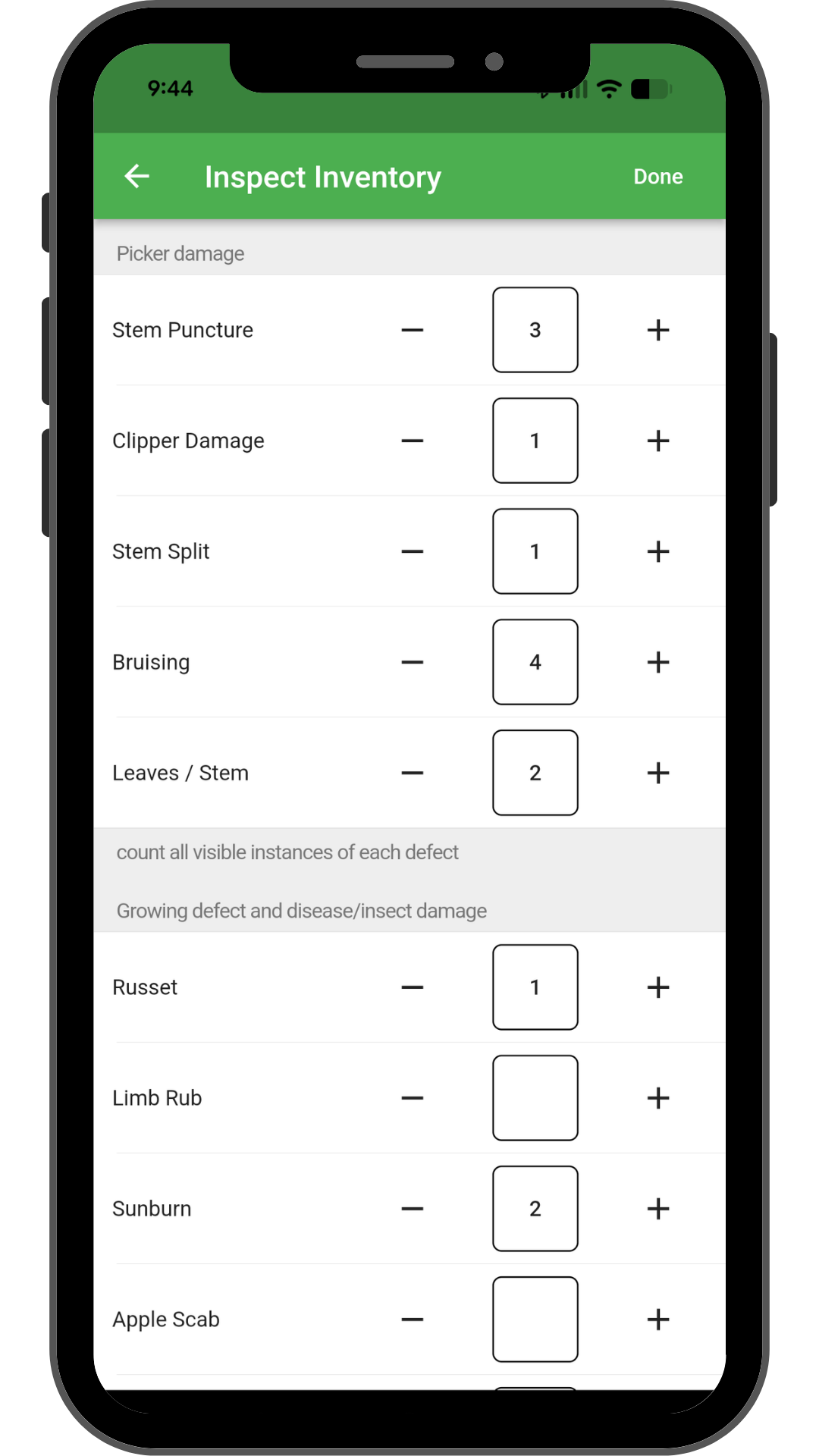

Once picking begins, the Quality Control module transforms from a recording tool into a real-time course correction system. Growers can build custom Inventory Inspection templates tailored to specific varieties. These inspections are linked directly to harvest events and specific workers, allowing supervisors to conduct representative sampling of bins as they are filled.

By identifying issues on the ground, like a crew leader noticing a sudden spike in bruising or under-colored fruit. In cases like this, management can intervene immediately before the defect continues into the rest of the block. This process is further enhanced by Harvest Quality VisionTM, which scans bins to monitor fruit size and color distribution without the need for manual measurement.

Monitoring productivity through the app also helps supervisors manage picker fatigue, a primary driver of fruit damage. By tracking progress and rotation, managers can ensure crews remain rested and focused. Whether reviewed on-site or remotely via the Croptracker dashboard, these live insights empower growers to protect their fruit quality at the most vulnerable point in the supply chain.

In an industry where the difference between profit and loss is measured in millimeters of color and the absence of a single bruise, growers can no longer afford to fly blind. By integrating precise picker monitoring and real-time quality control through Croptracker, orchards can shift from reactive management to proactive protection. Minimizing harvest defects doesn't just save a single apple; it secures the labor investment already spent, protects long-term storage inventory, and ensures that every bin delivered to the packhouse has the highest possible chance of hitting premium retail grade. In today's market, quality isn’t just a standard, it's a defense against thinning margins.