What is pressure / firmness?

Produce firmness is the measure of resistance offered by the fruit or vegetable flesh (pulp) to an applied external force, such as pressure or compression. It is primarily a critical indicator of texture, but also reflects the fruit's internal structural health, ripeness, and its ability to withstand handling and storage conditions. While chemical indices like sugar content (Brix) and starch conversion provide insight into flavor development and physiological readiness, firmness testing provides the indispensable metric of structural integrity and shelf life potential.

Firmness is universally regarded as one of the five most important parameters in fresh produce QC, evaluated alongside dry matter, soluble sugars, titratable acidity, and color. Commercial fresh produce QC operations rely on standardized units of measurement, primarily pounds-force (lbs or lbf), Newtons (N), and occasionally kilograms-force per square centimeter kgf/cm2. Quantifying firmness using these objective measures replaces the highly subjective "hand-feel" assessment, allowing for precise, repeatable quality grading.

What does softening mean for fruit quality?

The softening of fruit is a fundamental physiological change that occurs during the ripening process. Softening results from structural degradation within the flesh. Specifically, it involves the breakdown and modification of cell walls and a reduction in the adhesion between individual cells, resulting in a loss of rigidity. (If you have ever bitten into a ‘mealy’ apple or a too soft banana, you will be familiar with how cell wall break down impacts fruit quality.) Because these structural and textural changes are synchronized with the conversion of starches into sugars, water, and carbon dioxide, the firmness of the fruit is often cited as the easiest and most reliable physical measure of the ripeness stage.

In climacteric fruits (e.g., Apple, Pear, Banana, Avocado, Mango), softening is an expected, ethylene-driven process that is synonymous with ripening. Firmness is therefore treated as a critical indicator of remaining shelf-life potential. In contrast, non-climacteric fruits (e.g., Citrus, Grape, Strawberry, Pineapple, Cherry) do not undergo a significant ripening phase after harvest. Firmness is primarily an indicator of freshness and structural damage.

The assessment of firmness provides a necessary physical verification that complements chemical maturity tests. Ripening involves parallel physical (softening) and chemical (sugar accumulation/starch clearance) changes. While Brix testing measures flavor (sugar content) and Starch-Iodine testing measures maturity (starch conversion), firmness testing measures the essential structural durability.

A potential risk in QC is accepting a fruit lot that is chemically mature but structurally weak. For instance, an apple might achieve minimum Brix targets but possess low firmness, meaning its cell walls are already compromised and highly susceptible to mechanical injury (bruising). Therefore, the firmness reading is necessary for balancing flavor and sweetness targets with the required shelf-life durability, thereby ensuring that the product maintains its texture and appearance until it reaches the consumer.

When, why and by who is pressure tested?

Pre-harvest: optimizing timing for storage

Growers use pre-harvest firmness to schedule ideal picking times, ensuring fruit will last through storage and packing to reach customers without the product degrading.

For growers of high-value crops like apples, pears, and stone fruit, firmness is a primary index used to schedule harvest windows. Harvesting fruit when it is too soft can lead to a drastically short shelf life and high rates of bruising, while harvesting too early compromises eating quality.

Firmness measured at harvest is decisive for the fruit’s storage potential. For example, fruit intended for long-term storage, such as apples destined for Controlled Atmosphere (CA) facilities, must achieve a minimum firmness of 15 lbs or more.

Post Harvest: predicting shelf life and economic risk

Store and pack house managers assess the effectiveness of cold chain or in-transit storage conditions by monitoring for accelerated softening during transit and storage and prior to packing. Pressure testing determines the suitability of fruit for long-term cold storage and is used to monitor fruit in ripening rooms to ensure it reaches the correct stage for the retail market.

Firmness is a direct predictor of post-harvest economic risk stemming from mechanical injury and rapid deterioration. Bruise damage is a significant factor in post-harvest losses, and the risk of bruising is strongly and negatively correlated with firmness. If a batch of apples is harvested at 12 lbs instead of the ideal 16 lbs for CA storage, that batch should be automatically assigned to sale much faster, potentially to only local markets.

Retailers and consumers use firmness to gauge the remaining shelf life and determine the product’s readiness to eat. Product department buyers will assess firmness during incoming fruit quality checks and will reject fruit that is too soft and will not last long enough on the shelf for the inventory to be sold. Consumers will frequently assess fruit firmness as a way to determine buying by handfeel, (all of us have picked up and put back a too firm avocado when we need to use it in a dish right away).

Harvest and storage firmness ranges for pome and stone fruit

Apples and Pears

For pome fruits, firmness is the key determinant of storage longevity. Apples intended for long-term Controlled Atmosphere (CA) storage must consistently demonstrate flesh firmness above 15 lbs. Fruit intended for immediate fresh market sales can tolerate a slightly lower firmness, generally greater than 13 lbs. Some apple cultivars have more specific and precise storage firmness limited. For example, Gala apples intended for mid to long CA storage are targeted to have firmness greater than 17 lbs, while Fuji and the NY1 (SnapDragon) cultivars require firmness greater than 16 lbs.

Pears are also harvested at high firmness levels to ensure they withstand storage and can be ripened in a controlled environment later. Bartlett pears destined for long-term CA storage are judged ready for harvest when their firmness reaches an average of 19.5 lbs pressure, with a narrow harvest window of only four to seven days once this threshold is met. D’Anjou pears for long-term CA must reach 15 lbs. In contrast, ready-to-eat pears desired by consumers have a juicy, buttery texture that corresponds to a flesh firmness between 2 and 4 lbs.

Peaches and Nectarines

Quality control for stone fruit, such as peaches and nectarines, relies heavily on a firmness gradient that dictates the best path through the supply chain. Peaches picked for long-distance shipping require the highest firmness, typically in the 12 to 16 b range, to survive the rigors of packing and transport to regional warehouses. For fruit destined for medium-distance shipping or local farm markets, the acceptable range drops to 8 to 12 lbs. Fruit harvested with firmness below 6 to 8 lbs is considered to have high consumer acceptance, but requires exceptional care to avoid bruising and must be moved quickly. Peaches that achieve the ready-to-eat condition generally have a flesh firmness of only 2 to 3 lbs. Peaches that test below 8 lbs are more susceptible to developing mealiness at the wrong temperature.

Firmness scales and testing methods

The Magness-Taylor Standard (destructive penetrometry)

The Magness-Taylor (MT) test, using a specialized penetrometer, has long been recognized as the "golden standard" method in both research and industry for measuring ripeness-related firmness. All other firmness measurement technologies are typically correlated back to the results of the MT test.

The principle of the MT test is to measure the maximum force (F), denoted in standardized units (e.g., kg/cm2 or pounds-force), required to puncture the fruit flesh to a predetermined depth using a probe (plunger) of a standardized diameter.

The procedure requires carefully removing a disc of the fruit's skin before inserting the probe, rendering the tested fruit sample unsalable.

Although accurate, the MT method is also recognized as time-consuming and labor-intensive, often requiring a large sample size to obtain reliable average measurements for the entire lot.

MT testing utilizes penetrometers, which are essentially calibrated dynamometers. These instruments range from simple handheld analog fruit testers to advanced digital force gauges.

Digital units are increasingly favored because they offer features such as easier digital reading, max hold functionality, and instant unit conversion between Newtons, lbf, and kgf/cm2.

Guide for accurate penetrometer measurements

Consistency in sample preparation and application of force is paramount for generating reproducible and reliable firmness data. The procedure generally follows these steps:

- Sample Selection: Select a random sample of 15 to 25 fruits of uniform size and temperature. The sample must be representative of the lot being tested (e.g., 3% of the lot). It is essential to exclude fruit with internal defects, such as watercore, as these can yield erroneously high readings.

- Skin Removal: Before testing, a sharp knife or peeler must be used to remove a small disc of skin (approximately cm2 on opposite sides (cheeks) of the fruit, typically midway between the stem and the bottom. Removing the skin is crucial as it eliminates resistance from the peel, ensuring that the measurement reflects the actual firmness of the fruit flesh.

- Probe Selection: The appropriate plunger tip diameter must be selected based on the commodity. Tip size standardizes the surface area over which the force is applied, which is critical for reproducible results.

- Testing: Hold the fruit firmly against a hard surface. Force the penetrometer tip vertically and steadily into the pulp at a uniform speed, usually taking about three seconds.

- Depth Control: The tip must penetrate to a standardized depth, typically about 8 mm, or until the standardized break in the tip diameter or scribed line is reached. Some penetrometers are on a stand with a handle to help control and standardize the depth of the puncture.

- Recording: Record the maximum reading (peak force) shown on the gauge. For consistency, test both sides of the fruit (sun and shade sides) and average the readings to determine the batch's quality. Some penetrometers have digital data display and storage and using a digital QC template to record measurements from a manual tool can make this calculation process more automatic.

Standard Magness-Taylor penetrometer probe tip selection

| Fruit size | Example crops | Recommended tip diameter (mm) |

|---|---|---|

| Large / hard fruit | Apples, Asian Pears | 11 mm |

| Stone fruit / medium fruit | Peaches, Pears, Avocados, Nectarines, Kiwi | 6 mm - 8 mm |

| Small / soft fruit | Cherries, Grapes, Berries, Strawberries | 3 mm - 6 mm |

Advanced and non-destructive firmness measurement methods

Some newer and non-destructive firmness testing methods allow for rapid, whole-lot testing, minimizing product damage and maximizing efficiency. Using a traditional penetrometer can lead to inconsistent results because of variation in penetration speed.

Durometers and compression testing

Durometers are instruments that determine the force resistance of the fruit tissue to a small, standardized probe, typically 3 mm in diameter. These are often employed for softer fruits where full penetration with a penetrometer is messy or not possible. Proper use of durometers requires a two-point calibration: zeroing the device away from surfaces, and then verifying the high end by pressing it against a glass surface to read 100.

The tip of the durometer is pressed against the sample fruit and the firmness will be between the no resistance 0 and the 100 level hardness of the glass surface used to calibrate the tool. This scale is based on the ‘Shore Hardness Scale’ and is made specific for fresh produce using the ‘Durofel’ scale. Durometers do not require fruit samples to be cut or destroyed during testing and results are often more consistent than penetrometers.

Compression-based methods do not puncture the fruit but measure the force required to deform the fruit by a specific distance. These systems determine the "slope" of the force-compression curve, often yielding a Mean Chord Stiffness (MCS) value. MCS is cited as being the best indicator of fruit firmness for small, highly sensitive fruits such as cherries, blueberries, and strawberries, which are poorly suited for puncture testing. Compression testing tools often come with the advantage of automating data capture as they digitally record the sample results as it moves through the specimens automatically.

Near-Infrared (NIR) spectroscopy pressure predictions

While NIR technology is predominantly used to measure internal chemical attributes like sugar content and dry matter, it is increasingly being leveraged to predict physical traits like firmness. This involves calibrating NIR spectroscopy tools with many pressure tested fruit samples so the network used by the NIR tool can return an accurate pressure reading.

Penetrometers vs. Durometers at a glance

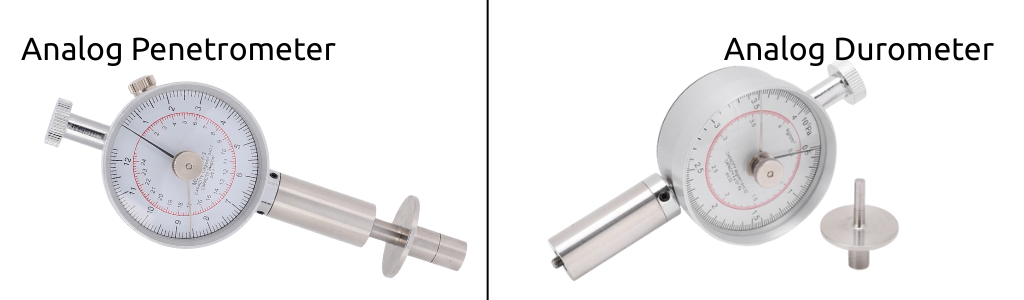

Two classes of instruments are used to measure firmness in fresh produce most commonly, penetrometers and durometers.

Penetrometers are designed to measure the maximum force required to puncture the fruit flesh to a specific, pre-determined depth using a standardized probe. This method is destructive, as it requires removing the skin and puncturing the fruit. Penetrometers use the Magness-Taylor scale.

Durometers measure the force resistance of the fruit tissue to a small probe, ~3 mm in diameter. Durometers are often used for softer fruits where full penetration is impractical, or in non-destructive compression methods for small, sensitive fruits like berries. Durometers use the Shore hardness scale.

Pressure testing, whether through the Magness-Taylor standard or modern non-destructive methods, is the indispensable physical verification that complements chemical maturity testing in fresh produce QC. The reading provides a quantitative, objective measure of the fruit's structural health, which directly dictates its texture, ripeness stage, and ability to withstand the supply chain.

For quality control, firmness is critical for balancing flavor development (measured by Brix and Starch-Iodine) with essential shelf-life potential. Ignoring firmness means risking the acceptance of fruit that is chemically mature but structurally weak and highly prone to bruising and rapid deterioration.

From the pre-harvest decision to the final retail check, firmness is a direct predictor of post-harvest economic risk. It determines a lot's suitability for long-term storage and its susceptibility to mechanical injury—the leading cause of post-harvest loss.

By applying consistent protocols and selecting the appropriate tools—be it a classic penetrometer for high-value crops or advanced compression/NIR methods for speed and precision—growers, packers, and retailers can move beyond subjective "hand-feel." Pressure testing provides the clear, actionable data necessary to guarantee product quality and maximize marketable yield from the field to the consumer's table.