The modern fresh produce supply chain operates under immense pressure to deliver consistent quality, minimize waste, and ensure timely distribution. Traditional quality control testing which relies on destructive sampling, chemical analysis and subjective visual assessments are slower, labor-intensive, and prone to measurement variability. To address these challenges, some fresh produce industry players are looking to the non-destructive quality assessment functions of Near-Infrared (NIR) testers.

What is an NIR tester?

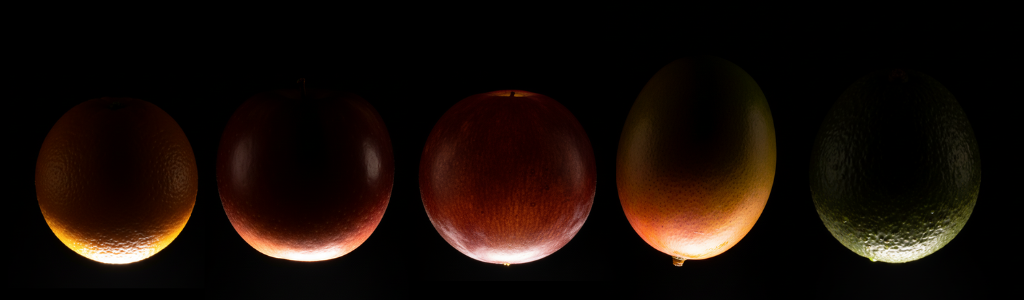

Near-Infrared (NIR) testing is a broad term with many applications. In this context, we are talking about NIR spectroscopy tools which quantify numerous internal quality properties simultaneously, including soluble sugars (Brix), organic acids, and dry matter content. QC teams are regularly testing for many of these metrics separately with a series of tests and tools, often resulting in destroying sample fruit. NIR readers will assess many of these qualities at once without having to lose any product to the sampling process.

What is a DA tester?

In fresh produce testing, some growers are also using a specialized form of hand held NIR tool called a DA meter. They are specifically engineered to monitor the degradation of chlorophyll by measuring the chlorophyll content in the plant’s leaves or fruit skin using the Index of Absorbance Difference (IAD) . The correlation to ripeness is inverse: as the fruit ripens, the chlorophyll breaks down, which leads to higher chlorophyll levels that indicate greener, less mature fruit. Once ripening is complete, the index reaches very low values. We have specifically defined DA meters as they are often sold as separate and cheaper NIR tools for specific crop types, but many fresh produce geared NIR testers will also return chlorophyll level results.

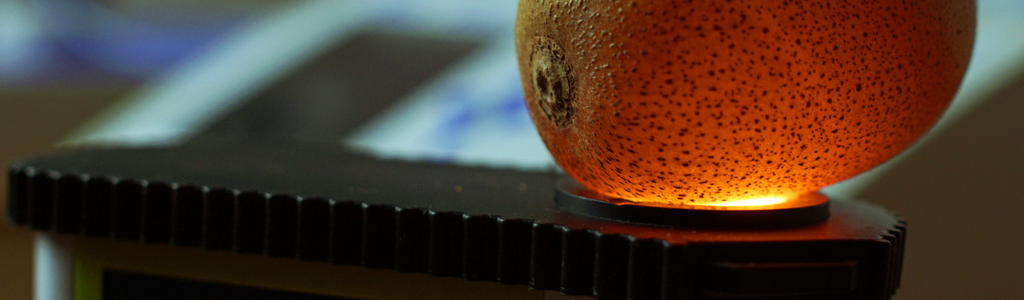

How do NIR testers work?

The physics of NIR light and molecular interaction

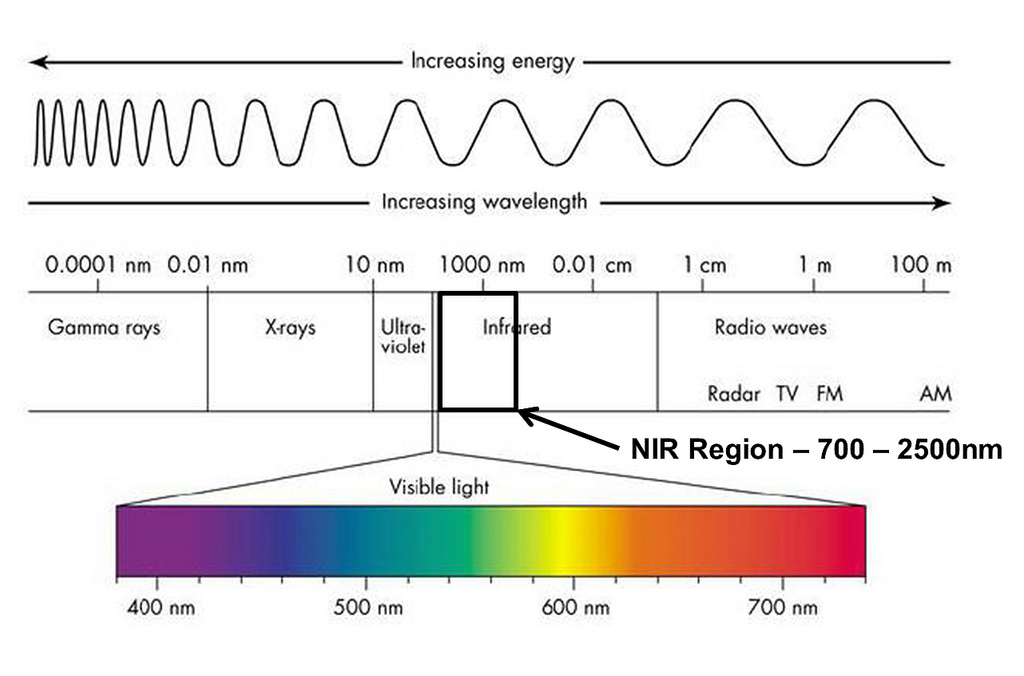

NIR spectroscopy is rooted in fundamental physics, utilizing electromagnetic radiation within the near-infrared spectrum, typically ranging from 700 to 2500 nanometers (nm). This range sits just beyond the visible light spectrum. The technique relies on the principle that all substances, including food products, emit electromagnetic radiation through the vibration of their molecules.

When NIR light is directed at a plant or piece of fruit, specific wavelengths of energy are absorbed by the substance’s molecular structure. This interaction is unique because different chemical bonds absorb different wavelengths of light. For fresh produce, the most critical components are revealed through specific molecular signatures and by analyzing the intensity of the light absorbed, the spectrometer can quantify the concentration levels of these components within the food product.

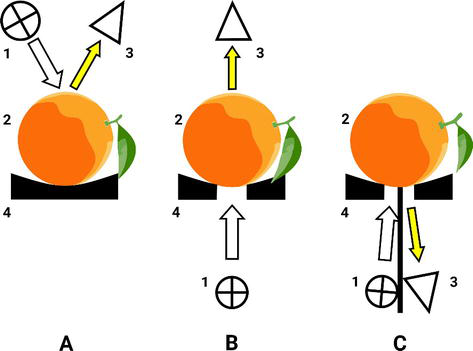

NIR instruments measure light that either passes through the sample (transmission) or is reflected off the surface (reflectance).

- Transmission: This method is highly effective for whole food items, such as intact fresh fruits. It requires the infrared light to pass through the sample, measuring the degree of light absorbed, which provides comprehensive insights into the internal composition and ripeness status.

- Reflectance: Generally employed for powdered or solid surfaces, reflectance measures the light scattered and reflected off the material.

- Interactivity: A combination of both reflectance and transmission principles, interactivity is frequently employed when analyzing fruits and vegetables to capture the broadest possible spectral signature.

The specific measurement method is chosen based on the commodity being examined and what is being measured. For example, DA meters use only Reflectance measurement methods to see chlorophyll content on the surface of the fruit.

NIR data translation and limitations

The raw output generated by an NIR spectrometer is complex, resulting first in a high-resolution graph illustrating the intensity of absorbed light across numerous wavelengths. This raw data and graph is too complicated for easy interpretation or operational use however and more NIR tools will be further programmed to return results in specific formats and scales for the commodity or crop they are developed for.

To convert this complex spectral signal into meaningful, actionable quality metrics (such as a percentage of soluble solids or dry matter), the data must be processed using chemometric models. Chemometrics is the application of mathematical, statistical, and computational methods to extract meaningful information from chemical data.

These models are developed through extensive, initial calibration, where the measured spectra are correlated against large reference datasets that have been rigorously verified using traditional laboratory methods. This means that NIR testing tools are not automatically suited for all commodities and anyone looking to introduce this testing into their workflow will need to ensure the tools are properly calibrated to their crop types.

While the benefits of NIR are immense, successful implementation hinges entirely on accurate, rigorous calibration. Chemometric models are not universally applicable; they must be custom-built using large databases of reference samples that have been thoroughly analyzed and verified using verified traditional laboratory methods (e.g., oven drying for dry matter, refractometers for Brix). The process of model development is expensive, time-consuming, and highly specific to the product. Models often require customization for individual varieties, specific growing locations, and targeted quality traits.

Despite its versatility, current Vis-NIR spectroscopy has one primary technical limitation: it is unable to precisely estimate texture or firmness. Consequently, NIR systems must often be complemented by other measurement tools, like a penetrometer, for pressure testing.

What are portable NIR tools used for?

Pre-harvest field testing

Portable, hand-held NIR and DA meters enable QC personnel to conduct objective audits directly in the field, eliminating delays in data collection from having to conduct sampling in a laboratory. Maternity can be measured throughout a growing area without destroying or even harvesting samples. Many portable NIR tools can be used while a fruit is still attached to the plant.

Post-harvest storing and grading testing

After harvest, NIR sensors are indispensable for in-line sorting and grading systems within packaging houses. We have written about pack line NIR use in our packline article series. Using a portable NIR tester prior to sending fruit down the line can lead to more efficient packline use, allowing for more optimal inventory groupings that will result in more consistency and less line stops to set up more drops. Additionally NIR data will improve storage and shipping decision making, ensuring fruit with large differences in maturity and quality is not stored together.

NIR metrics for fresh produce

General NIR analyzers provide a single, powerful solution for assessing a wide range of internal quality parameters simultaneously. This comprehensive profile is essential for both maturity assessment and predicting consumer acceptance, and while each of these metrics can be attained with different testing methods, the NIR reader can do it all at once. We have outlined some of the most common metrics for fresh produce below.

Brix° Value

Degree Brix, is the industry standard for quantifying fruit sweetness, reflecting the total amount of dissolved solids, primarily sugars. NIR spectroscopy non-destructively quantifies sweetness by detecting the various bonds present in carbohydrates, which are the molecular components of sugars. NIR predictive models are successfully used for assessing Brix° across a vast array of produce, including apples, pears, kiwi, tomatoes, and citrus fruits.

Dry Matter (DM) Content

Dry matter (DM) includes all non-water solids within the fruit, such as sugars, starch, lignin, pigments, and phenols. DM content is a well-established and highly reliable indicator of maturity and serves as an excellent predictor of final ripe fruit quality post-harvest. NIR spectroscopy is the only current non-destructive method capable of accurately estimating DM content.

Destructive DM content testing is conducted using the Oven Drying method where the fresh fruit is weighed before and after drying and the ratio between the fresh and dried weight is the dry matter content. Dry matter testing is used in many produce items, including apples, avocados, kiwi, mangoes, potatoes, dates, melons, blueberries and more. Crops destined for drying, like dates or prunes, rely on dry matter testing to predict their post processing yields.

Titratable Acidity (TA)

Titratable Acidity (TA) measures the concentration of organic acids, which dictate the fruit’s sourness or tanginess. For optimal flavor, the balance between sugars and acids is essential. Similar to DM, NIR spectroscopy is the only non-destructive method for measuring TA to quantify organic acid compounds. The citrus, grape, and tomato growers in particular rely on TA measures to determine processing potential.

Moisture, Internal Color and Defects

Beyond the primary flavor metrics, NIR provides rapid assessment of other essential quality traits:

- Moisture Content:

By detecting specific chemical bonds, NIR provides precise measurements of moisture content, which is vital for determining the fruit’s freshness, texture, and expected shelf life, greatly impacting storage and logistic decision making. - Internal Color:

NIR light can penetrate up to ~7 mm into the fruit pulp, making it the only non-destructive method capable of estimating internal color and pigments. Color is a key ripeness indicator in crops like avocados and is very important for grapes used in winemaking. - Disease and Defect Detection:

A substantial advantage of NIR technology is its capability to detect internal diseases or structural defects that are not externally visible. This early detection prevents the spread of pathogens throughout the inventory and significantly reduces post-harvest losses, making it an invaluable proactive management tool.

Chlorophyll Levels

As mentioned above, chlorophyll levels can be used to assess fruit ripeness, a key metric for harvest timing and storage decision making. Using an NIR tester for chlorophyll effectively functions as an objective, electronic replacement for traditional, subjective color charts. It helps more accurately assess ripeness as it eliminates the subjective nature of color assessment and provides more consistent data that is not dependent on lighting or the human eye.

In published research, chlorophyll values at harvest have been correlated with post-storage quality indices, including firmness, sugars, and acids in specific apple cultivars. The specialized measurement, calibrated to apples, provides a temporal metric for quality control, defining how far along the maturation curve a fruit is, serving essentially as a reliable pre-harvest clock. Quality assurance and harvest teams can leverage the DA meter pre-harvest to identify the optimal picking window based on storability potential, and then utilize the broader NIR system post-harvest/pre-packing to confirm that the measured sugar/acid profile meets flavor specifications.

NIR benefits and conclusion

The adoption of NIR testing and data into fresh produce quality control processes offers profound benefits that growers and marketers can see quickly:

- Speed and Efficiency:

NIR provides instantaneous results for many QC data points at once, with some portable devices generating actionable data in as little as 8 to 12 seconds per scan. The speed dramatically streamlines QC processes, allowing producers to test significantly more product and drastically reduce the labor and material costs associated with slow, laborious traditional methods. - Waste Reduction:

By eliminating the necessity of sacrificing high-value fruit for chemical analysis, non-destructive testing results in zero product loss during the QC testing before and after harvest. - Precision and Consistency:

NIR technology minimizes human subjective error and provides objective, highly consistent numerical results. This precision helps meet rigorous consumer expectations and maintain high-quality standards. - Sustainability:

By reducing post-harvest waste, optimizing resource utilization, and increasing the overall efficiency of quality evaluation, the integration of NIR technology contributes directly to more sustainable agricultural practices.

The adoption of Near-Infrared (NIR) spectroscopy and the specialized DA meter represents a transformative shift from reactive, destructive quality control to proactive, non-destructive quality assurance in the fresh produce industry. These technologies provide objective data essential for optimizing every phase of the supply chain.