In our previous article, we discussed the external factors that influence fresh produce packing—things like market demands, logistics, and internal quality metrics that the packline cannot "see." But what about the attributes the packline can see?

A packline is able to “see” most of the factors impacting fruit and vegetable “grade.” A grade is a specific standard of quality used to classify and sort fruits and vegetables. These grades are not related to nutritional value, but rather to a set of physical characteristics and an allowable tolerance for defects. The purpose of grading is to create a consistent and uniform product that meets consumer and market expectations.

Grading standards are typically established by government or industry bodies and provide a common language for buyers, sellers, and inspectors. The standards can vary depending on the country and the specific product and increasingly are dictated by brand standards. In this article, we'll dive into what a packline's advanced technology can measure and how this data is used.

What the packline “sees”

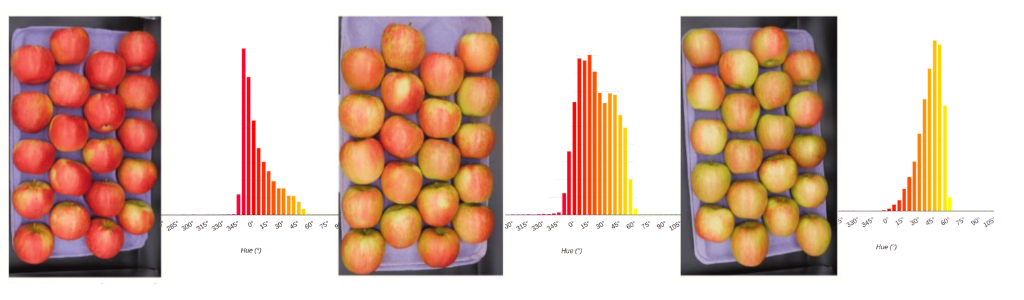

Color

Packline sorters will use color information to see defects and anomalies that impact fruit grade but for many fruits, color itself is a deciding factor impacting grade. In apples for example, color intensity thresholds are set per grade and some varieties, like Pink LadyⓇ, will only meet brand standards at specific color thresholds.

The packline operator or fruit company defines specific color standards for each fruit variety. These standards are programmed into the system. For example, a "Premium" grade for an apple might be defined as:

At least 50% of the surface area is a "dark red" color.

No more than 20% of the surface area is "green."

A "dark red" color is further defined by a specific range of numerical values within a color space model like the L*a*b* color space.

To make color quantifiable, the system uses color space models, such as the L*a*b* or HSV (Hue, Saturation, Value) model. These models assign numerical values to color, allowing for objective measurement. For example, in the L*a*b* model:

L* (Lightness): Ranges from 0 (black) to 100 (white).

a* (Red-Green Axis): Positive values are red, negative values are green.

b* (Yellow-Blue Axis): Positive values are yellow, negative values are blue.

By setting specific ranges for these values, the system can precisely define what constitutes "dark red," "light red," "green," or "yellow."

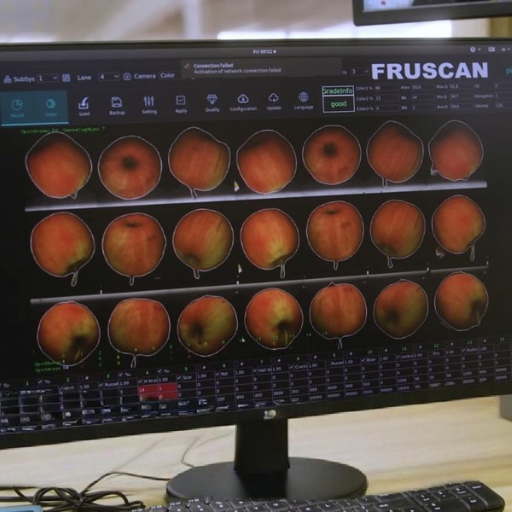

A packline uses advanced optical systems to perceive color. These systems are typically comprised of:

High-Resolution Cameras and Sensors:

Multiple cameras are positioned around the conveyor belt or roller system to capture images of each fruit as it passes. This setup often provides a 360-degree view, ensuring all sides of the fruit are inspected.The cameras are equipped with high-resolution sensors that capture the light reflected by the fruit's surface to ‘see’ the color.

Illumination:

Controlled lighting, often with LED light sources, is crucial. This provides a stable, uniform light environment, preventing shadows and external light from interfering with the color analysis. Some systems can even adjust for different lighting scenarios (e.g., bright, medium, dull) to ensure consistent results.

Image Processing Software:

The data from the cameras and sensors is sent to a computer with specialized image processing software. This software analyzes the images in real-time, converting the captured light data into quantifiable color values. It can also be powered by artificial intelligence (AI) and machine learning, allowing the system to "learn" and continuously improve its accuracy.

As each fruit passes the cameras, the software performs a rapid analysis. It isolates the fruit from the background, identifies different color patches on the fruit's surface. It then calculates the percentage of the fruit's surface area that falls into each defined color category (e.g., dark red, medium red, green) and detects defects and blemishes based on color deviations and patterns.

Defects

A produce packline's ability to "see" defects is a sophisticated process that relies on highly advanced camera and AI technology and pre-programmed standards. A packline doesn't just look for a single "defect" but rather a wide range of imperfections, both external and internal. It uses a combination of different technologies to do be able to ‘see’ defects:

High-Resolution Optical Cameras (Visible Light):

These cameras, often the same ones used for color grading, are the primary tool for detecting surface defects. The image processing software is trained to identify specific patterns, colors, and textures that deviate from the standard for a healthy fruit. For example:

Bruises:

Bruises often appear as discolored, typically brown or black, patches. The software can be programmed to recognize the subtle color change and measure the size and depth of the blemish.

Scabs, Spots, and Discolorations:

The system can spot diseases, like apple scab or citrus canker, which manifest as small spots or discolorations.

Skin Breaks and Punctures:

The cameras and software are sensitive enough to detect even small skin breaks or punctures that might not be immediately obvious to the human eye.

Near-Infrared (NIR) and Hyperspectral Imaging:

This is where the packline's capabilities go beyond human vision. NIR and hyperspectral cameras capture light in a spectrum that is invisible to us. Different materials and conditions reflect and absorb NIR light in unique ways, allowing the system to see what's happening beneath the fruit's skin.

Internal Bruising:

A fresh bruise that is not yet visible on the surface will have a different moisture content and cellular structure. NIR imaging can detect these subtle differences, identifying a bruise before it even discolors the skin.

Watercore:

This is a disorder in apples where the inner tissue becomes water-soaked. It's invisible from the outside, but NIR technology can detect the change in density and light absorption.

Decay and Internal Rot:

As a fruit begins to rot, its chemical composition changes. These changes can be detected by hyperspectral imaging, which captures data across a very narrow and specific range of light wavelengths. This allows the system to identify the early stages of decay, even if the fruit looks perfect on the outside.

A packline doesn't "know" a defect in a human sense; it operates based on a precise set of pre-defined rules and artificial intelligence. Certain grade metrics are numerically translated and programmed into the packline's software by the manufacturer and some defects the packline will be ‘trained’ to see by its operators.

Some defects will be specifically annotated and labelled for the packline to learn and increasingly, the packline is identifying defect patterns itself using sophisticated AI and machine learning algorithms. Instead of a human programming every single defect, the system is "trained" using thousands of images of both good and bad fruit.

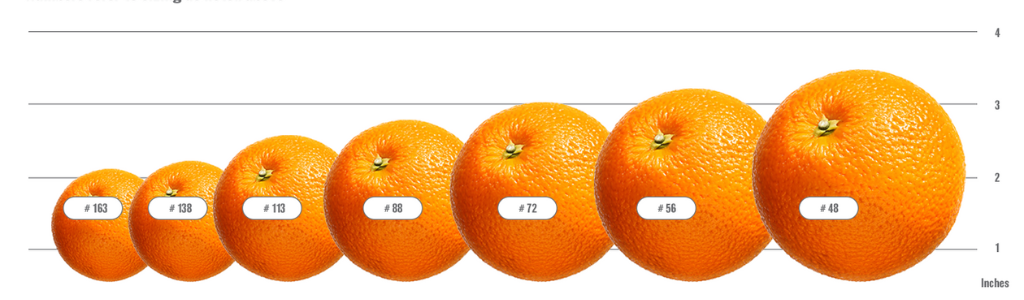

Size

Most packaging configurations will have minimum weight requirement, size range requirements and, in the case of tray/carton packs, count requirements. Before the run begins, the operator programs the packline with specific size and weight ranges for each grade. These are based on market demand and industry standards. To accurately accomplish this, a modern packline uses a combination of two primary methods to measure each fruit: optical sizing and precision weighing.

Optical Sizing (for Diameter and Shape)

This technology uses the same high-resolution camera systems as color grading, but with different software algorithms. As each fruit rotates or moves under the cameras, the system captures multiple high-resolution images from all angles (often 20+ images per fruit). This ensures that the entire surface is captured, regardless of how the fruit is positioned.

The specialized software processes these images to perform a 3D reconstruction of the fruit's shape. It calculates key dimensions:

Maximum Diameter (Caliber):

The widest point of the fruit. This is a common industry standard for sizing.

Length and Width:

The system can measure the fruit's dimensions along different axes.

Volume:

By combining the dimensional data, the software can accurately estimate the fruit's volume.

Irregular Shapes:

This method is particularly effective for fruits with non-uniform shapes (e.g., pears, mangos). The 3D reconstruction ensures that the grading is not based on a single, potentially misleading, measurement. The software can also be programmed to detect and reject fruits with irregular or undesirable shapes.

Precision Weighing

Packline’s weigh individual fruit most commonly using the following elements.

Individual Weighing Trays:

As the fruit moves along the packline, it is gently placed onto small, individual carriers or rotating trays or cups.

Load Cells:

Each carrier is equipped with a highly sensitive electronic scale called a load cell. As the fruit passes over the load cell, it records the exact weight in real-time, typically to a high degree of precision (e.g., within a few grams).

Real-time Data:

Weight data is instantly transmitted to the central computer system. The system can be calibrated to account for the weight of the carrier itself (tare weight), ensuring only the fruit's weight is measured.

Precisions sizing ensures that fruit is sorted consistently, efficiently, and with minimal human error. It allows fruit companies to meet precise quality specifications from retailers, optimize their product value, and reduce waste by sorting fruit for different markets (e.g., fresh consumption vs. processing).

The importance of data visibility

Given all the factors influencing how fresh produce is packaged, the packline operator's job is incredibly complicated. They must coordinate with shipping and storage teams, manage traceability for both food safety and growing payments, take into account quality information the packline does not know, and meet sales orders in time. Compiling and organizing all the data needed to make informed packing decisions is an important component of improving packouts and increasing profits.

The most effective packline operations are data-driven. The packline itself is a sophisticated but blind instrument. Its advanced cameras and sensors can only 'see' a limited range of physical attributes. The real intelligence behind successful packing lies in the operator's ability to synthesize and act on a complex web of external data that the machine cannot perceive. This includes everything from real-time sales orders and long-term marketing plans to the shelf life requirements of different shipping routes and the post-harvest history of each fruit lot.

The ROI of data-driven decisions

When a packline operator has all this information in a unified, accessible system, it transforms the packing process from reactive to proactive. They can minimize waste by matching fruit quality to the appropriate market, they can reduce the amount of fruit that is downgraded or discarded. Optimal packing increases profit margins.

Packing for multiple markets simultaneously is only possible when the operator can match specific inventory to specific orders in real time. This agility ensures that high-value fruit ends up in high-value packs. By ensuring the right quality of fruit goes to the right destination, operators can maintain consistency and meet customer expectations, strengthening long-term business relationships.

The future of packline efficiency isn't just about faster machines or smarter cameras; it's about making the invisible visible. It's about providing the human operator with all the data they need, organized and instantly available, to turn a complex, reactive process into a streamlined, profitable strategy.