Located north-east of Toronto, Algoma Orchards stands out for its longevity and agricultural excellence. For over 50 years, Algoma has been family run and has cultivated and processed quality apples, building a legacy rooted in reliability, innovation, and a deep commitment to sustainable practices. As a leading grower, packer, and marketer of apples, producing 2 million boxes of apples and up to 10 million liters of apple juice annually, Algoma Orchards continuously seeks advanced solutions to maintain its high standards.

Algoma Orchards: A Legacy of Sustainability and Growth

Spanning over 1,600 acres with a million+ trees, Algoma Orchards grows popular varieties like Gala, Honeycrisp, Ambrosia, and McIntosh. Their state-of-the-art 160,000-square-foot packing and storage facility, with plans for further expansion, processes fresh apples and produces juice for major retailers across Canada. Sustainability is central to their operations, evidenced by their use of trickle irrigation, over 30 years of Integrated Pest Management (IPM), automatic frost fans, and a slender spindle planting system. Their commitment extends to their facilities, featuring over 60,000 square feet of rooftop solar panels and Tesla storage batteries, powering 55-60% of their energy needs. These efforts have earned them multiple accolades, including the Minister's Award for Environmental Excellence and the President's Choice Sustainability Award.

Croptracker is proud to be part of this pursuit of excellence and has significantly enhanced their operational efficiency and traceability. For this spotlight interview we spoke with Deon Boonzaier, Plant Manager and Marius Kriel, General Manager at Algoma. Deon handles the quality, storage, packing and processing end of the business, while Marius straddles the orchard and plant processes, ensuring a smooth transfer of information from the field to the plant.

The Croptracker Advantage: Consolidating and Streamlining Operations

Algoma has had access to Cropracker’s suite of software since our partnership with the Ontario Apple Growers (OAG) began. Originally, Manus Boonzaier, Farm Manager at Algoma, was the heaviest user of Croptracker, logging all Algoma’s pesticide and fertilizer applications using the Spray module. Recognizing the value of digitizing their record keeping, Algoma then began to track their harvest inventory and employee time using Croptracker’s Harvest and Punch Clock modules respectively.

At the beginning of the harvest season, Manus and Marius will generate harvest bin tickets from Croptracker, printing tags for each of the growing areas they will be harvesting based on their yield estimates. Algoma follows the Croptracker Pre-Printing Harvest workflow, which allows these tags to be activated as bins are filled in the orchard. This flow makes it easy to generate more tags as needed and does not require waiting for in-orchard printing. Tags can be generated in bulk, saving on printing costs. When these tagged bins arrive at the plant, Deon and his team are able to easily track the movement of these labelled bins and associate quality information and storage location information with the original harvest record, ensuring accurate traceability and informing packing and sales decision making.

Algoma also receives Croptracker tagged bins from other OAG members in the area, who send their apples for storage and sale through Algoma’s plant. Algoma is able to track the received inventory for reporting back to the grower about the quality and pack out totals, ensuring greater accountability and traceability.

Quantifiable Benefits: Time and Cost Savings

Croptracker is an essential tool in our eyes

Deon praised Croptracker's flexibility and user-friendliness, noting how easily supervisors can manage tasks via the mobile app. The shift from paper to digital records has revolutionized reporting and payroll processes, offering quicker access to information and reducing the burden of manual data entry. "The ease of pulling the information up is always better in digital format…quicker access, better for reporting. Plus, we hate paper over here." Deon states, emphasizing the farm's embrace of digital efficiency.

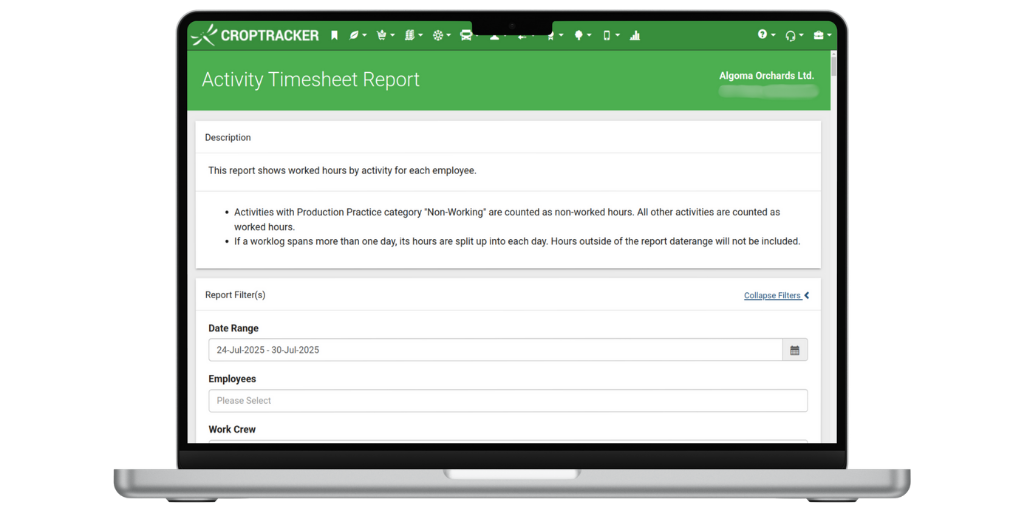

For analyzing efficiency and costs in the plant and the orchard, Marius makes frequent use of Croptracker Punch Clock reports, including the Activity Time Sheet Report. Marius uses it to meticulously track pruning costs for specific blocks and monitor crew productivity, even comparing the same team's performance day-to-day to identify areas for improvement. Deon was quick to highlight the power of comparing labor usage across different farms, which helps them "measure and challenge group productivity".

While quantifying exact monetary savings can be complex, both Marius and Deon recognize significant gains since adopting more of Croptracker’s functionality. They both noted that Croptracker saves "management time," which is "more expensive than the time spent on data entry by multiple people". While it takes time to log information in the field, this time is more than made up for with the time saved in reviewing the data by management. Marius adds a clear financial benefit: "we're definitely saving a person for sure," eliminating the need to hire an additional employee for data organization. Their processes no longer require hours of data entry and consolidation to find the information needed for payroll or operational decision making.

Algoma Orchards' successful integration of Croptracker exemplifies how modern agricultural technology can drive efficiency, ensure traceability, and empower growers with the precise data needed to thrive in a competitive market. Looking ahead, Deon is hoping to move forward with digitizing the quality inspection process at the plant using Croptracker’s Quality Control and Starch Quality Vision modules. Croptracker is eager to work on this project and continues to partner in Algoma’s journey of growth and innovation.