Spray and chemical inventory records are some the most important documents a produce grower can have. As well being a legal requirement in most jurisdictions, they are becoming increasingly sought-after by processors and buyers as a means to verify the safety of a farm's products. Spray records can also provide useful insights that can help growers plan their future operations. When complete with Post-Harvest Interval (PHI) information, they also demonstrate that due diligence was taken and help protect the safety of growers, workers, and consumers.

With the recent widespread media attention on pesticides and incidents of their misuse, growers may wish to investigate new ways of recording their chemical application and inventory information more uniformly and more accessibly. In this blog post we discuss how Croptracker makes keeping accurate, comprehensive, and secure records quick and easy.

Benefits of Keeping Highly-Detailed Spray Records

• Comply with regulations

• Gain access to opportunities with more buyers and food processors

• Demonstrate compliance in the event of a complaint or inspection

• Plan for the future by modelling, in high-detail, future sprays schedules on past successful ones

• Identify possible contributing factors for positive and negative results experienced after a spray

Keeping Spray Records with Croptracker

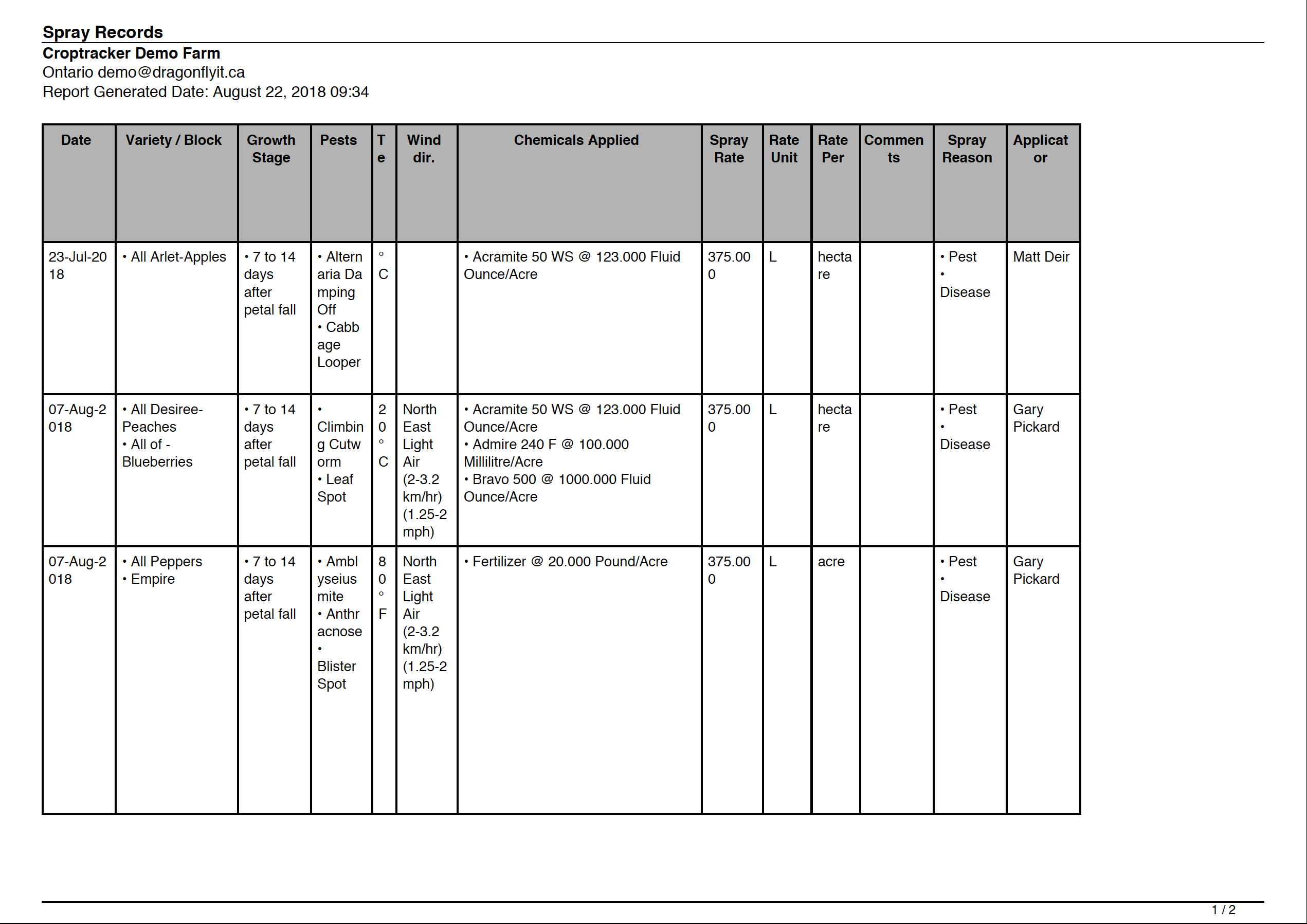

Comprehensive Spray Reports

Spray reports are generated in a single click and can give you or an inspector a wealth of information about your past sprays - namely the:

• Date of Application

• Variety & Block

• Growth Stage Pests

• Temperature

• Wind Direction

• Chemicals Applied

• Spray Rate

• Rate Unit (eg. L)

• Rate Per (eg. hectare)

• Comments

• Spray Reason

• Applicator Name

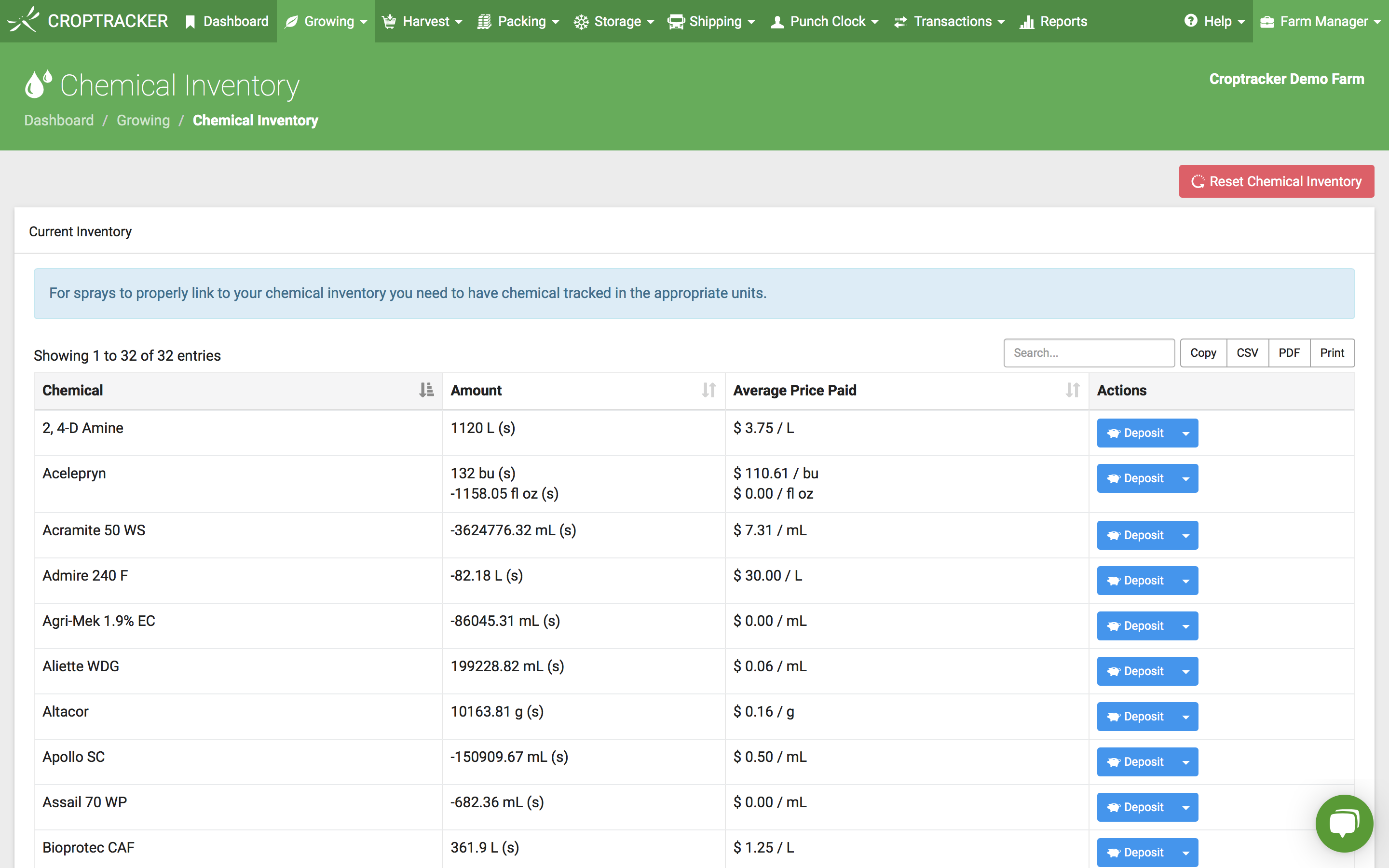

Automatically-Updated Chemical Inventory

Croptracker can pull up your chemical inventory in real-time and automatically adds or deducts from it based on recorded sprays or purchases.

Accuracy

With Croptracker's mobile apps, sprays can be recorded as they happen in-field - there's no need for growers to wait until they're back in their offices to record them. This reduces the chance of forgetting the fine details of an application and producing inaccurate records.

Planning Ability

Croptracker users can also create Spray Plans in advance. Spray Plans are a great way for growers to plan out and visualize their upcoming season's chemical usage.

Time Savings

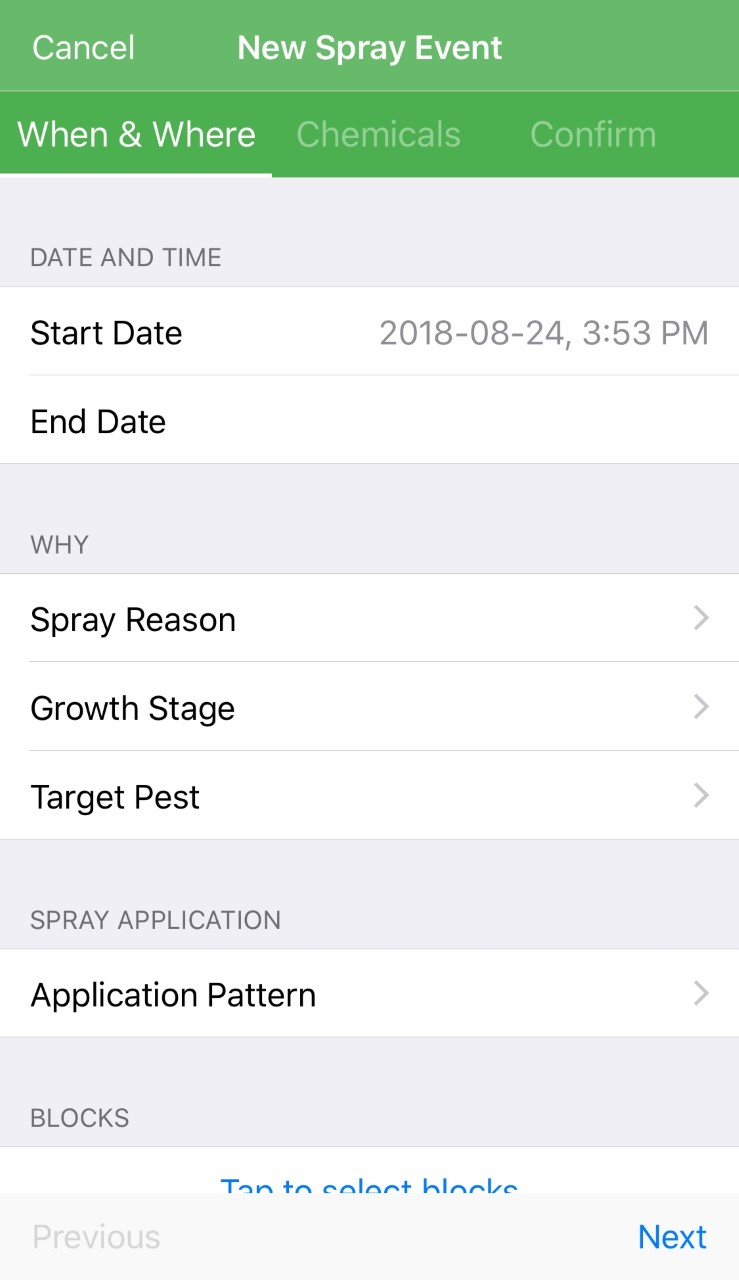

Croptracker's intuitive desktop and mobile Spray Event input wizards make accurately recording sprays faster and easier than ever.

To further expedite the process, Croptracker remembers past entries so you can record repeat sprays in seconds. You can also browse through 396 Treatment Templates, common chemical applications that you can use to populate a spray record, or add your own.

Automatic PHI Interval Notifications

Helping keep horticultural workers safe is one of Croptracker's top priorities. With our automatic Post-Harvest Interval notification system, growers can be alerted when the intervals have passed and when it's safe for workers to return to the field.

Retention & Easy Accessibility

You may be required to hold onto spray data for up to several years. Croptracker stores and backs-up all your data in one safe, easily-accessible location. This frees up space in your office and eliminates the headache of manually archiving and later locating years-old spray data.

Need a refresher on any of Croptracker's features? Head over to our Knowledge Base, where you'll find step-by-step tutorials as well as common troubleshooting tips and more. And as always, if you're ever stuck, never hesitate to e-mail us at support@croptracker.com or Live Chat with us by clicking the green speech bubble ![]() in your bottom right-hand corner. We're always happy to help you let Croptracker make your farm become more efficient, safe, and profitable!

in your bottom right-hand corner. We're always happy to help you let Croptracker make your farm become more efficient, safe, and profitable!

| Missed Last Week's Blog Post? Introducing Harvest Quality Vision |