Speciality fruit and vegetable growers and packers are facing pressure from all sides. In an increasingly consolidated market with steep labor and input costs, it can be difficult to gain any competitive advantage.

One of the strategies produce marketers have gone to more in the past few years is specialty, mixed variety packaging. A unique or curated mix of produce can be a key differentiator in a crowded market. A producer can brand a special "garden salad mix" or a "heirloom tomato medley" to attract consumers and potentially command a higher price point.

In this Croptracker use case blog we will outline how growers can maintain traceability requirements and productivity while creating mixed variety packed products in the field, greenhouse or from storage.

The visual appeal of a colorful and varied product can attract consumers and lead to impulse purchases. A well-presented mixed fruit platter or a vibrant vegetable stir-fry mix is more enticing on a store shelf than a single, plain item. For the consumer, a mixed pack is often more affordable than buying the same amount of produce in individual containers.

For producers, packing mixed products directly in the field can streamline the supply chain by eliminating a separate step in a packing house. This can reduce handling, labor costs, and the time it takes for a product to get from the field to the consumer, which is crucial for maintaining freshness. However the challenge of maintaining strict traceability standards, like the impending FSMA204 rule, complicates the process and causes some producers to avoid mixed packed products.

What works best in a mixed variety pack?

Controlled atmosphere / greenhouse grown crops are the most common mixed variety packed products due to the ability to much more closely plan for and optimize harvest times. Given stable lighting, temperature, fertilization and watering, CA growers are able to know when exactly a crop will be ready to harvest and can be sure to have several varieties ready at the same time to be packed together. Salad green mixes are the most common example of course, but mixed tomatoes and pepper variety packers are being promoted more and more as the greenhouse industry has advanced.

Long-term storage crops are ideal for mixed-variety fresh produce packs because they have a longer shelf life and a slower, more predictable rate of ripening. This makes it much easier to manage the logistics of combining different crops and varieties that would otherwise spoil at different times. Combining these is also a way of reducing waste and ensuring less popular varieties don’t languish in storage.

For example, potatoes are well-suited for mixed packs due to their durability and long-term storage potential. After harvest, potatoes are typically "cured," a process that hardens their skin and heals any minor wounds, making them resistant to rot and moisture loss. These days, mixed color/variety potatoes are an expected offering at most grocery stores.

Mixed pack example workflow

In the fall harvest season, squash and pumpkin mixed bulk bins are often displayed just outside the store. In this use case article, we will use a mixed pumpkin bin as an example to demonstrate how to maintain individual harvest yield records while creating combined products with unique and traceable labels. The workflow uses the Harvest and Packing modules.

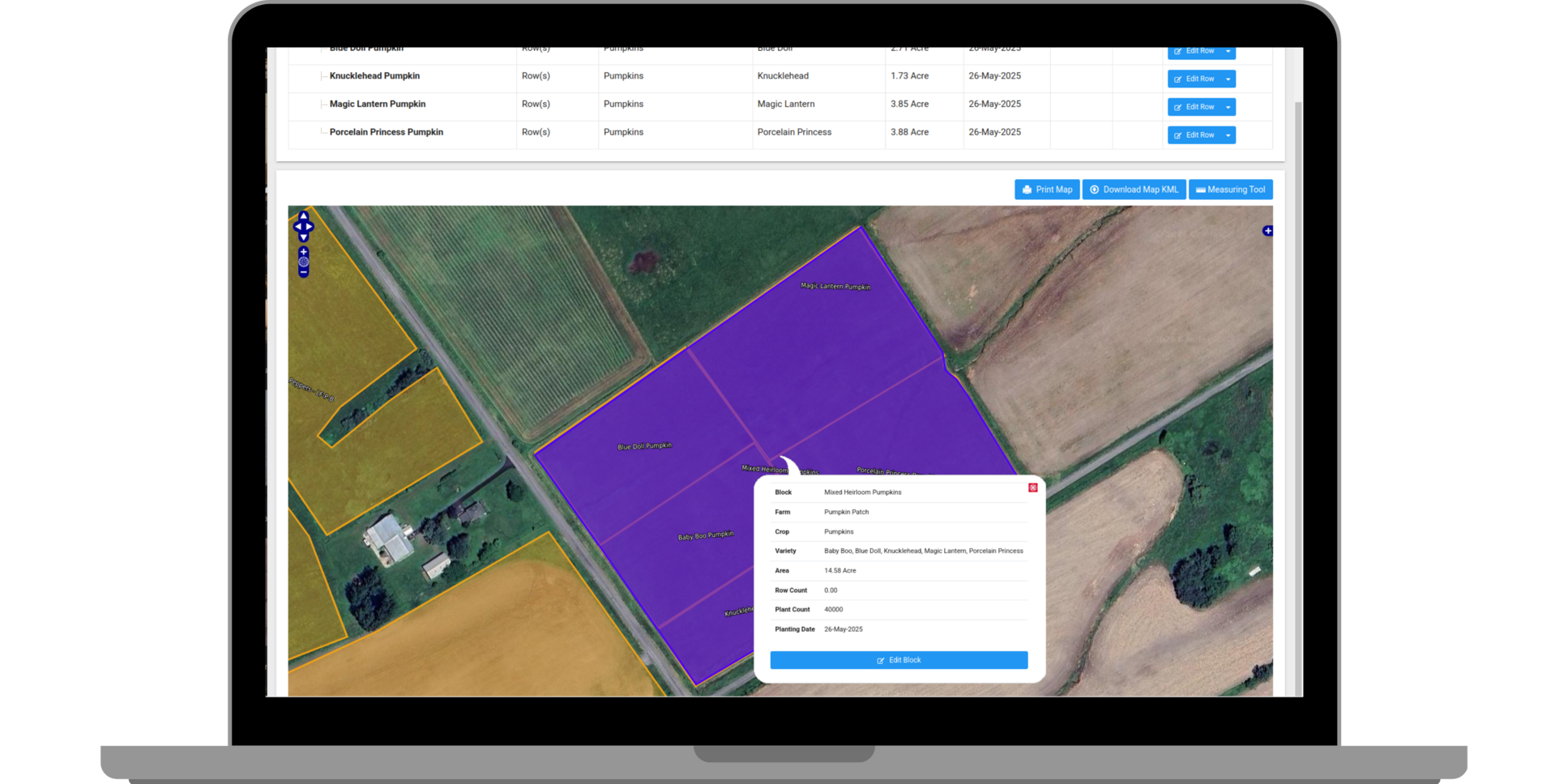

In Croptracker, setting up a mixed variety packing workflow starts with setting up the growing areas, i.e. Farms, Blocks, and Rows. The biggest component of produce traceability is maintaining a record of the origin growing area, and Croptracker support staff make sure to help users structure their growing regions to best support their harvest and packing workflows. The following example is set up to support a scenario where several different varieties of pumpkins are taken from the field and packed together by hand.

Once the maps are in place, the next step is to set up a Product using the Packaging Materials, Master Style and Pallet configuration in Croptracker’s Packing module. In this example, we are using one large cardboard box, about the size of a pallet, as our Packing Material, so there will only be one ‘Master’ case per pallet. All varieties that will go in the mixed pack box have been included in the Product setup. This is the last set up step before moving to the field and Croptacker mobile app for harvest.

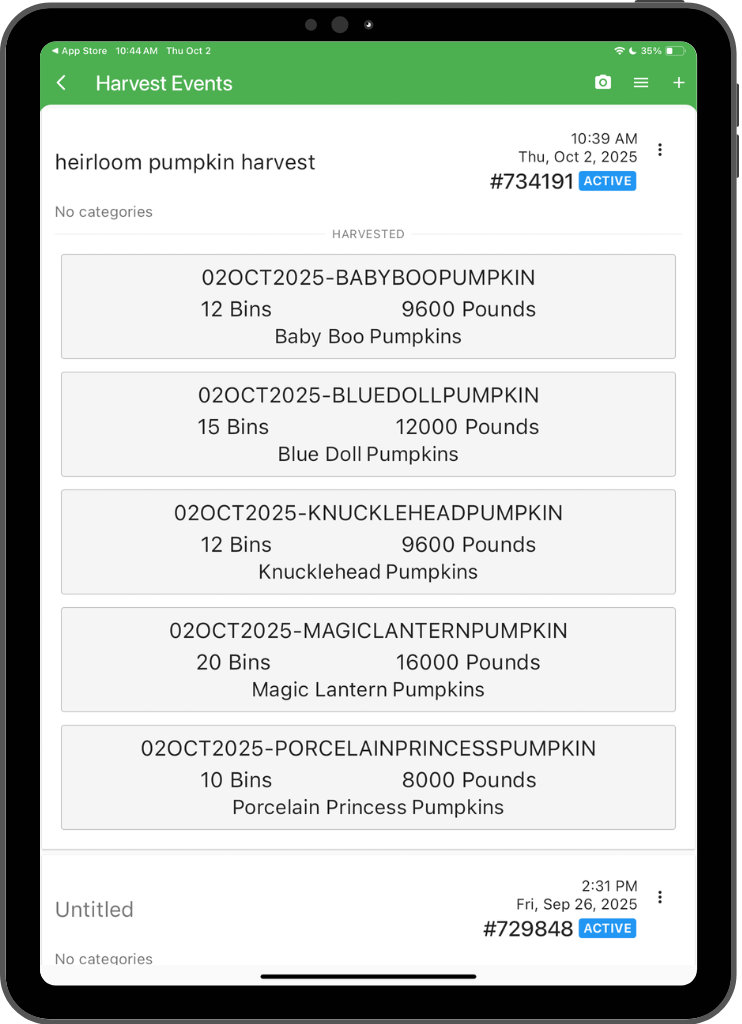

In our example harvest, the pumpkins have all been cut from the vine two weeks ago, have cured in the field, and are ready to go to retail right away. Workers in each variety section are moving pumpkins into reusable harvest containers that will be moved to a central location in the field to be combined with the other varieties. As single variety bins are filled and moved to a central location, a worker is using the Harvest module on the app to quickly log the total volume of each variety.

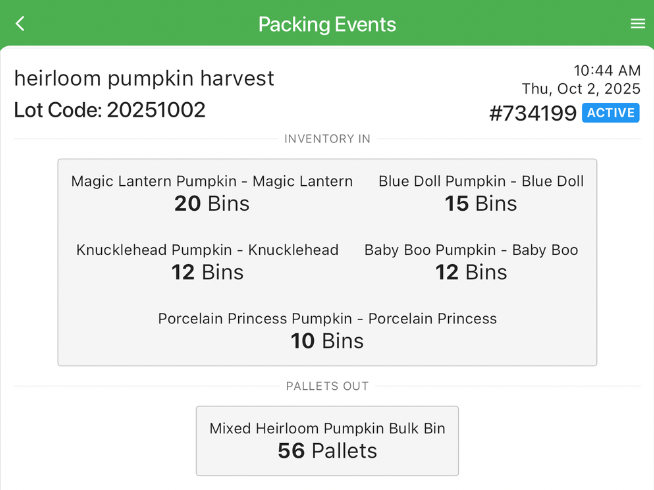

As single variety bins continue to arrive at the packing spot, a user on the mobile app will create a Packing event. As workers take some of each variety and fill the mixed retail bins, packed inventory is created in the app with unique and traceable codes. Product pallet labels are printed using a mobile field printer and applied to each full bin. Note, many growers choose to print pallets tags a few times to ensure all sides of the bin are labelled.

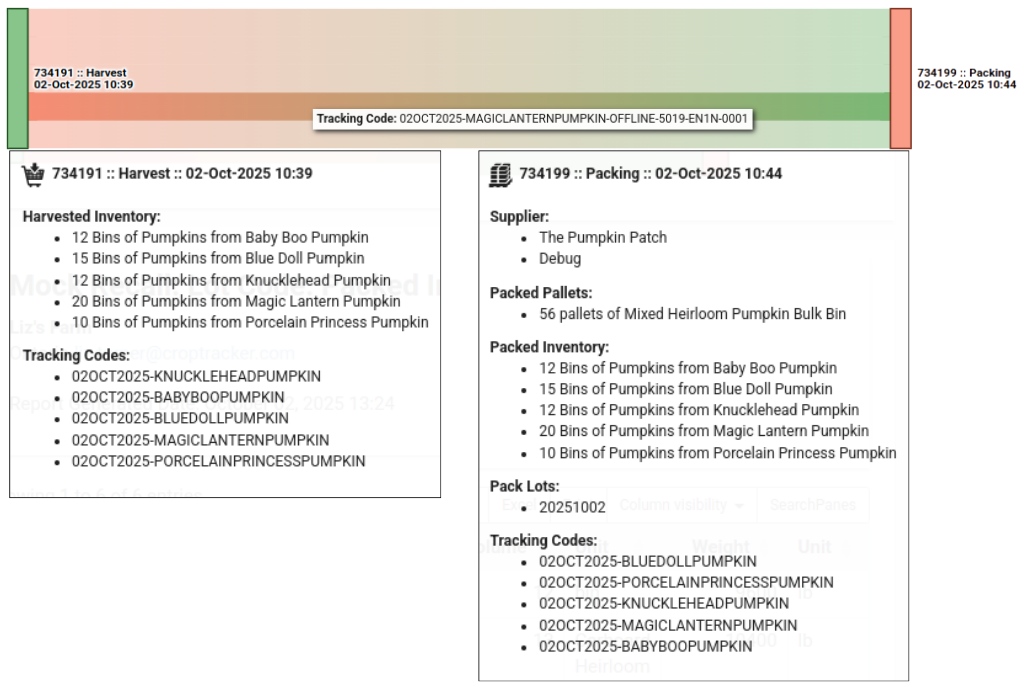

To ensure full traceability and accurate yield records, all the harvested inventory created today will be added to the packing event. This will create an inventory trail that is easy to follow through Croptracker reporting, satisfying auditor and customer information sharing requirements. Below is a section of Croptracker’s Mock Recall report which can be used to visually trace pack lots back to their origin (and forward through Storage and Shipping when recorded). This report will display the details of the harvested inventory as well as the packed product output.

In a competitive and often challenging market, specialty fruit and vegetable growers are finding new ways to differentiate themselves. Mixed-variety packs can be part of a solution to gain a competitive advantage, attract consumers with visual appeal, and potentially command a higher price.

However, the key to successfully implementing this strategy is maintaining meticulous traceability—a requirement that can seem daunting, especially with new regulations on the horizon. As we've shown with the Croptracker mixed pumpkin workflow, technology can simplify this process. By using a solution that tracks products from the field to the final packed bin, producers can meet traceability standards with confidence. If your team is being slowed down by mixed pack traceability record keeping, get in touch with Croptracker to walk through your workflow with our support staff. Learn how Croptracker helps satisfy customer and auditor requirements and creates a more efficient and profitable operation, turning a potential challenge into a distinct business opportunity.