It’s a new year, and while harvest time has wrapped up here in North America it is still underway in the southern hemisphere. Every year we get feedback from hundreds of growers worldwide about their need for harvest traceability, but who are also desperate to simplify their data collection process during the busiest time of year.

Bin tagging is the most concrete step you can take to ensure inventory traceability, but there’s no one size fits all solution for every farm. With Croptracker, bin tagging is more than just sticking on a label: Croptracker’s harvest module organizes your data by harvest events and pulls information about each piece of inventory you harvest.

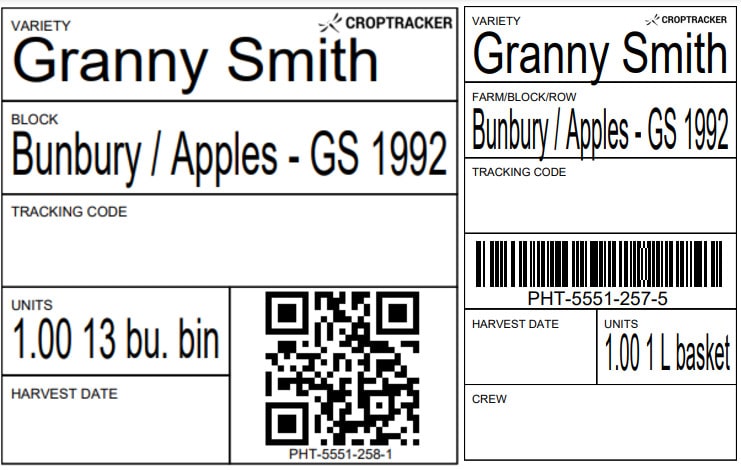

Croptracker offers a variety of built-in label formats to meet your needs and integrate with your existing harvest workflow. Tracking inventory using tags with a barcode or QR code means you can attach more data to a tag than just what is printed - employees can scan a code to view additional information about the event, or see data summarized in a harvest report.

Barcodes vs QR codes

Storing a number of readily accessible data points in a single image revolutionized data collection and object tracking. One-dimensional (1D) barcodes came first: invented by Norman Joseph Woodland and Bernard Silver, its composition was based on Morse code, extended into thick and thin bars. This design gained broad commercial success in the 1970s with automating the supermarket checkout system, a process that remains similar to current day with the ubiquitous Universal Product Code (UPC) barcode on retail products. As of December 31, 2019, the Canadian Produce Marketing Association (CPMA) stopped issuing generic UPC numbers for fruit and vegetables. Company and brand specific UPC numbers are now the barcoding standard in North America.

The QR code - abbreviated from Quick Response codes - are a particular type of 2D barcodes invented in the 1990s by Masahiro Hara from Denso Wave, a Japanese automotive company. A unique pattern of black squares are arranged in a square grid on a white background, with information present in both horizontal and vertical components of the image. QR codes are used in tracking, ticketing, marketing and in-store product labelling.

Both code types are used in harvest bin tagging workflows. What your farm or packhouse operation chooses to implement might depend on the inventory tracking software used, or what devices are most accessible for work crews to use for scanning. QR codes hold a major contemporary advantage because of the proliferation of smartphones, which easily scan and redirect the user to the info associated with the code.

Choose the bin tagging approach that’s based on your specific workflow

Tagging in real time (Read-only)

Enter tag info in real time during the harvest and then print in the field or send the print job to the packhouse’s cloud-linked printer station. A new Harvest event auto-generates a scan code and entry options for things like location information, who picked, and more. The Read-only selection is ideal for vertically integrated operations – create only the tags required to avoid confusion and printing waste.

Integrating external tags with Croptracker (External Tag - Handheld Barcode Scanner or Camera)

Combine the system that already works for you with the Croptracker tools that will further elevate operational performance. That’s the idea behind the External Tag options in the Harvest module. Whether work crews are equipped with barcode scanners or smartphones for QR code capture, Croptracker will validate that a tag created by another system is unique.

This scan code preference is best suited for operations that want to use Croptracker’s Harvest Quality Vision to accelerate the size and color grade sorting process. Croptracker can associate the existing tag with an HQV scan as it's taken.

Pre-printing (Croptracker Harvest Tag Set - Handheld Barcode Scanner or Camera)

Skip all the data entry on-site. By generating thousands of labels in advance of work crews heading out to pick, supervisors can distribute tags for particular blocks and rows.

Scan your bin tags at every step

Your harvest tag will follow your inventory through the product’s entire lifecycle, from seed to sale. Scan a tag when receiving at the packhouse – a crew member operating a forklift can use a mounted tablet to assist in directing bins to the right areas for processing, storage, and shipping.

View and generate audit reports

At the end of the harvest, Croptracker can organize and display your farm records in easy-to-read reports that can be generated with just a click. Reports summarize your data, so you can see a high-level overview of your entire event - but that individual tracking information will always be available to connect each bin to its history.

Croptracker develops agtech solutions for industry leaders. Located in Eastern Ontario, Canada, our mission is to make crop production safer, more efficient, and more profitable. Designed in partnership with fresh market producers and distributors, every tool we create is based on direct industry feedback. Croptracker’s award-winning farm software optimizes recordkeeping, labor tracking, production and cost management. Our integrative Harvest Quality Vision technology offers instant empirical analysis of crop samples exactly when you need it. Optimize your harvest season with Croptracker’s customizable solutions. Visit Croptracker.com to learn more about our products and contact us for app based solutions.