In this Croptracker Use Case blog, we will go over the in-field inventory and labour tracking features that help berry growers create inventory and pay records on the go. We will go through how Croptracker’s Field Pack module is designed to keep pace with harvest by integrating barcode scanning, offline piece tracking and custom product tagging. This is part two in a series on berry harvesting. To read part one where we detail some of the unique challenges facing berry growers, click here.

Addresses the Need for Speed at Harvest and Uncomplicating Payroll

To help berry growers overcome the challenges we outlined in part one, and to make harvest processes safer, more efficient, and more profitable, Croptracker has developed specialized workflows with our Field Pack and Punch Clock modules. The following section includes some definitions and details about these features and their benefits.

Berry Product Set Up

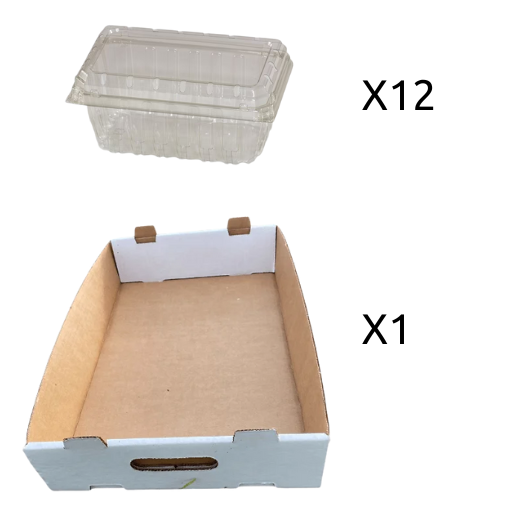

When growers who harvest into consumer containers in the field start using Croptracker, one of the first steps our onboarding team will help them do is configure their product set up. This step allows for the creation of a combination of containers and labels with a specified weight when filled to create ‘masters’. Masters are what the berries are packed into in the field.

Users are then able to specify how many of the masters create a full pallet. Both master and pallets can be set up to meet specific buyer’s needs. Setting up these masters and pallets also allows for the tracking of packaging material use and costs. The table below shows an example of this product configuration and labels for strawberries.

| Packaging Materials | Master | Product Pallet |

|---|---|---|

|

|

|

Boosting Accuracy

Traditional paper piece tracking is prone to errors and missing information. In order to ensure accurate inventory and worker records during harvest time, berry growers using Croptracker use the employee badge and master tag scanning feature. Before sending a crew out to harvest, supervisors will print master tags and ensure all employees have their employee badges. In the field, masters filled by growers are activated and allocated to pallets when scanned into Croptracker and can be linked directly to the picker using their employee badge.

This process allows for the linking of harvest time, location, variety, inventory and employee details all in one step, ensuring proper traceability. Croptracker also works offline in fields with low or no connectivity meaning you don’t have to wait to create accurate digital records. Having this level of granularity and real time record keeping allows for informed decision making during harvest and after to inform the next harvest.

Maintaining Quality and Speed

Many growers using this Field Pack workflow will boost the speed by pairing a barcode scanner with the Croptracker app. Using a barcode scanner is faster than relying on the phone camera. When a picker comes up with a stack of filled masters, supervisors scan the employee badge and the case tags, creating inventory records against specific employees in seconds. You don’t need expensive or hard-to-find hardware to start this workflow. Croptracker pairs with any bluetooth barcode scanner featuring keyboard wedge more (a standard feature on most).

Multiple field supervisors can be doing this process at once and managers are able to view progress remotely on their own app or from their browser to assess harvest progress and available inventory - sharing this information with sales and logistic teams before the berries are even out of the field.

As pickers are at work, supervisors or quality control team members can simultaneously inspect and record quality details about the harvest using the Quality Control module, linking these records directly to inventory and the picker. Supervisors can also record employee performance information, informing managers of issues that would require retraining or reorganizing workers.

Saving Valuable Manager Time

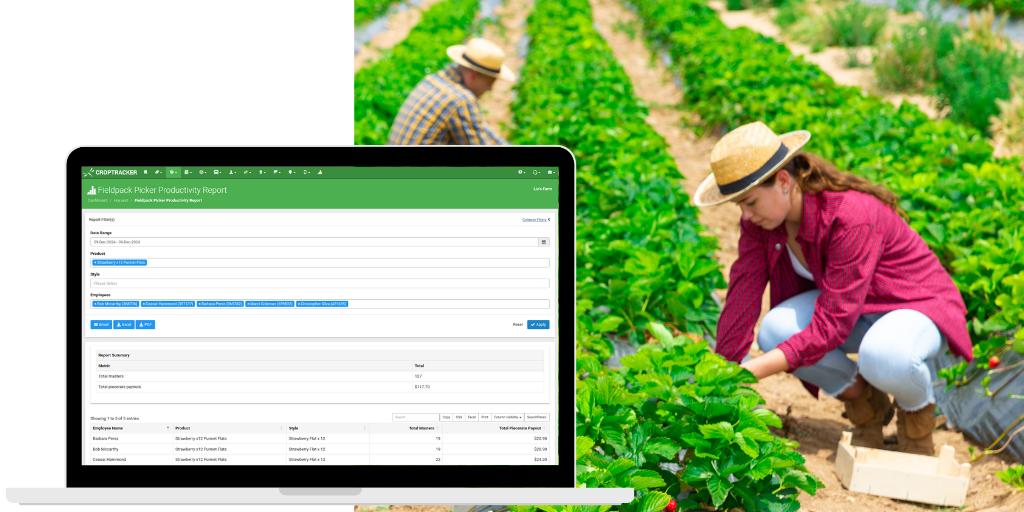

In addition to speeding up record keeping in the field, using Croptracker for berry harvesting saves significant time for managers and administrators. Croptracker users report saving hours, sometimes days of work, using Croptracker’s payroll reporting. The Piecemeal Pay Report and the Fieldpack Picker Productivity Report are very popular with our berry growing users.

During and after harvest, managers are able to review worker and inventory records and can adjust and correct mistakes efficiently with tools like the Punch Clock Admin screen. This tool is used to quickly adjust worklogs as needed, such as adding breaks or punch out times if the employee forgot to badge out.

Administrators are also able to quickly add or adjust hourly and piece rate pay information and assign these to employees for automatic pay calculations. Employees can also be quickly added to Croptracker and shift between work crews whenever needed. New employee badges can be generated with a click.

Information analysis is made much easier with digital record keeping in real time. At a glance, managers are able to see when packaging material needs to be reordered, when employees need retraining, when a specific crew is lagging behind, what inventory is available for sale, when a harvest linked to an order is complete and ready to ship and much more.

Building Worker Trust and Retention

One of the features users find most valuable about on the go harvest piece recording is the accuracy and transparency provided for employee management. Supervisors in the field can easily validate the recorded information with the inventory and employee present, and give feedback to employees about their progress in time for them to adjust their speed or technique as needed.

Work receipts can be printed in the field to give to pickers to validate with their supervisors. Admin users are able to send email work hour summaries to employees at the end of the day, week or pay period to help workers validate their pay and ensure disputes can be solved quickly. Users are also able to set up a system to reward good work using picker bonuses and flag workers who would be good candidates for crew leads.

Ensuring Customer Loyalty

Using the Field Pack module also helps maintain buyer and customer loyalty due to a closer monitoring of quality and inventory movement. If there is a problem with a shipment, it can be tracked back to the source and the issue can be corrected so it does not happen again. Quality oversight can be shared and validated by more people in the organization with records relating to various stops in the supply chain. It is also easier for buyers to obtain the traceability information they need for food safety compliance rules and product labels from Croptracker can support GS1 standard formats for seamless inventory management at receiving.

While berry harvesting presents significant challenges related to labor management, inventory tracking, and quality control, solutions like Croptracker's Field Pack offer a clear path forward. By leveraging features like in-field scanning, offline functionality, and integrated quality control, growers can boost accuracy, streamline payroll, and ensure end-to-end traceability from the moment a berry is picked. This digital approach not only saves valuable time and reduces administrative burdens, but it also fosters greater trust with employees and customers by providing transparent, real-time data that ultimately strengthens the entire operation.