Navigating the Global Produce Market: The MRL Challenge

In today's interconnected world, agricultural producers face a complex web of regulations, few more critical than Maximum Residue Limits (MRLs). These limits define the maximum permissible levels of pesticide residues on food products, set by importing countries to safeguard consumer health. The allowable chemicals, best practices and consumer perceptions are constantly shifting. While MRLs are essential for food safety, their global variations and frequent changes create significant hurdles for growers, packers, and shippers.

Non-compliance with MRLs isn't just a minor setback; it can lead to costly shipment rejections, substantial financial penalties, and severe damage to a business's reputation. The challenge is compounded by the fact that MRLs are not harmonized worldwide, meaning a product compliant in one market might be non-compliant in another. Restrictions on chemicals used and how much is tolerated are stricter in some markets, including Europe. Failing to provide proof of sprays applied and in what concentrations can result in loss of market access entirely. This dynamic environment demands a proactive, precise approach to farm management.

The Cornerstone of Compliance: Impeccable Spray Records

At the heart of MRL compliance lies meticulous spray record-keeping. These records are your verifiable proof that pesticides were applied correctly, within legal limits, and with appropriate intervals before harvest. They are fundamental for demonstrating adherence to Good Agricultural Practices (GAP) and other food safety standards, acting as a critical gatekeeper to global markets. Increasing calls for transparency in chemical use are coming from end customers as well.

Beyond regulatory mandates, robust record-keeping offers immense operational benefits:

- Liability Protection:

- Documented proof of correct application provides crucial liability protection in case of inquiries.

- Improved Decisions:

- Detailed records inform future crop rotations and help assess pesticide effectiveness.

- Worker Safety:

- Records ensure proper Personal Protective Equipment (PPE) use and track Restricted Entry Intervals (REI), preventing workers from entering unsafe areas.

- Cost Savings:

- Accurate records optimize pesticide purchasing and minimize waste.

Crucially, Pre-Harvest Interval (PHI) and Re-Entry Interval (REI) tracking are paramount. PHI, the minimum time between application and harvest, directly prevents MRL exceedances by allowing residues to dissipate. Meticulous management of these intervals is vital for both MRL compliance and worker safety.

Key Data Points for MRL Compliance in Croptracker's Spray Module

| Data Point | Relevance to MRL Compliance |

|---|---|

| Pesticide Name & Active Ingredient | Identifies specific chemicals for MRL check; ensures authorized use. |

| Application Date & Time | Establishes a timeline for PHI calculation and adherence. |

| Location (GIS) | Links application to specific fields/blocks for targeted compliance and traceability. |

| Weather Conditions | Provides context for chemical efficacy and potential drift, influencing residue levels. |

| Application Rate & Tank Mix Details | Verifies adherence to label instructions and Good Agricultural Practice (GAP) for proper dosage. |

| Pre-Harvest Interval (PHI) | Crucial for confirming sufficient time for residue dissipation before harvest. |

| Re-Entry Interval (REI) | Ensures worker safety by preventing premature entry into treated areas. |

| Personal Protective Equipment (PPE) | Documents adherence to worker safety standards during application. |

| Target Crop/Pest | Confirms pesticide use on authorized crops for specific MRLs. |

| Total Spray Costs | Supports financial analysis and optimization of chemical usage. |

| Applicator/License Info | Verifies that applications are performed by qualified personnel. |

Croptracker's Integrated Solution: Your Digital Shield

Croptracker offers a comprehensive, modular farm management software, including Spray record keeping, designed to centralize information, streamline operations, and ensure compliance from planting to shipping. Its integrated modules provide the visibility and control essential for navigating MRL complexities and securing global market access.

Precision Spray Management: Proactive Compliance

Croptracker's Spray module is an all-in-one solution for digitizing spray record-keeping. It captures critical data points, including date, time, location, weather conditions, and specific fertilizer and pesticide applications.

![]()

A standout feature for MRL compliance is the module's automated monitoring of PHI and REI. Croptracker can alert workers of safe re-entry and pre-harvest intervals before they enter an area. This proactive alerting system is vital in preventing premature harvest or re-entry, directly mitigating the risk of MRL exceedances. Growers like Enza Zaden praise this capability for providing "peace of mind" during surprise inspections, allowing them to retrieve PHI/REI chemical history in seconds.

The system also manages chemical inventory and costs, simplifies tank mix calculations, and allows for customized rules and restrictions to be incorporated into digital spray applications. This ensures adherence to Good Agricultural Practices (GAP) and regional standards, preventing over-application and ensuring proper intervals are honored.

End-to-End Traceability: From Field to Fork with Confidence

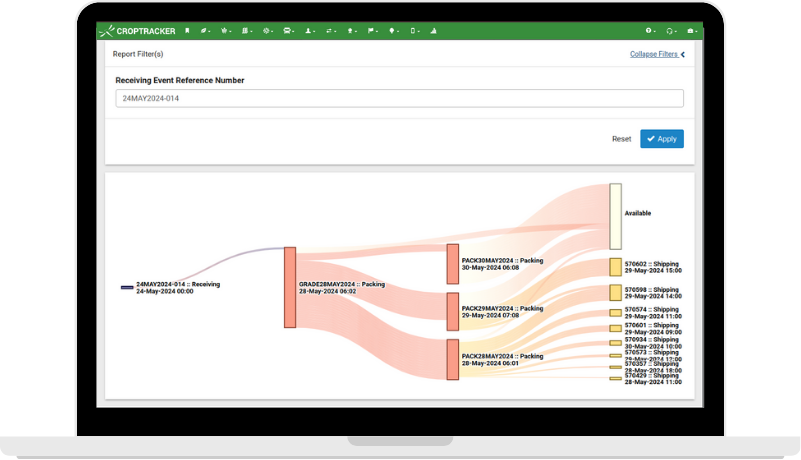

Croptracker excels at creating a seamless data flow, linking spray records with subsequent post-harvest activities. It connects spray events to harvest, packing, and shipping data using unique Traceability Lot Codes (TLCs). This establishes a comprehensive "seed to sale" data trail, providing unparalleled transparency and traceability throughout the supply chain.

By linking specific spray applications—and their associated PHI/REI—to specific harvested lots, Croptracker provides an auditable, verifiable chain of custody that confirms MRL compliance before the product even leaves the farm. This robust capability is crucial for effective risk management and for meeting stringent food safety requirements across global markets.

Effortless Reporting: Audit-Ready, Export-Ready

Croptracker's Analytics and Reports module is designed to quickly streamline all your data into single reports for auditors, retailers, and more. It can instantly generate reports, including those formatted for USDA Spray Audits and GAP compliance.

To meet diverse international market requirements, Croptracker allows seamless data export in various formats, including CSV, Excel, or PDF. This flexibility is paramount for providing information in the precise formats mandated by different regional pack houses, auditors, and importing countries. During typical audit processes, being able to generate records on demand is required.

The ability to be "audit-ready" at any moment significantly reduces the administrative burden and stress traditionally associated with audits. Customers like Sandhar Farms report saving "hours during audits" simply by printing out a report. Hollabaugh Bros. Inc. relies on Croptracker to easily validate that harvested products have passed their pre-harvest interval times, a critical aspect for satisfying demanding pack house reporting requirements.

![]()

Real Growers, Real Results: Success Stories with Croptracker

The tangible benefits of Croptracker are evident in the experiences of growers worldwide. Click through to these customer case studies to learn more.

- Scocan Holdings: This pineapple farm significantly reduced audit preparation time. Scott Maxwell, a farm owner, noted saving "easily an hour of paperwork after we spray" by transitioning to digital spray plans and records, ensuring compliance with PHI/REI requirements.

- Hollabaugh Bros. Inc.: Having adopted Croptracker over a decade ago, this farm leverages the system for regulatory compliance, annual GAP audits, and adhering to EPA’s Worker Protection Standard. They use Croptracker's extensive chemical lists, including PHI/REI times, to validate that harvested products meet pre-harvest interval requirements for pack houses.

- Enza Zaden's Florida R&D Station: Station Manager Antonio Canales III experienced profound "peace of mind" during audits. He can quickly filter Croptracker spray reports and retrieve specific chemical history, including REI and PHI information, in mere seconds, confirming that Croptracker "touches all the bases on all of the critical points that the auditors and inspectors want to see".

- Sandhar Farms Ltd.: This expanding operation transitioned from manual notebooks to Croptracker, saving "hours during audits, especially for spray and GAP," by simply printing out reports on demand for their chemical and fertilizer applications.

These success stories underscore how Croptracker empowers growers to streamline operations, enhance compliance, and confidently expand their market reach.

Secure Your Future in the Global Produce Market with Croptracker

The complexities of Maximum Residue Limits and the non-harmonized global regulatory landscape present formidable challenges for agricultural producers. Croptracker stands as an indispensable partner in navigating this intricate environment.

Croptracker's integrated farm management software, particularly the powerful Spray module, equips growers with the precision tools needed for proactive MRL compliance. From meticulous data capture and automated PHI/REI monitoring to end-to-end traceability and robust, audit-ready reporting, Croptracker ensures adherence to the strictest international standards.

By centralizing information, automating critical processes, and providing secure, accessible digital records, Croptracker not only ensures MRL compliance but also optimizes operational efficiency, reduces risk, and secures a competitive edge in the global produce market.

Ready to simplify MRL compliance and expand your market reach? Request your free private demo of Croptracker, including our robust Spray module, now and discover how our award-winning farm management software can transform your operation.