Last week we took a look at computer vision; what it is, how it works, and some of the applications for computer vision in agtech. This week we’ll go over some further applications for machine vision technology in autonomous vehicles, drone and UAV monitoring and mapping, and quality assurance.

What is Computer Vision?

In case you missed last week’s article, computer vision or machine vision typically refers to the use of machine learning or deep learning algorithms in image processing to allow a machine to “see” and identify objects around it. Different computer vision technologies may use a variety of camera types to act as the machine’s “eyes” depending on the imaging requirements.

Autonomous Vehicles and Machine Vision

In the case of fully autonomous vehicles, an accurate computer vision system is essential. In typical vehicles, hazard detection, navigation, and object avoidance all depend on a human operator. For autonomous vehicles, with no driver or remote control abilities, just setting a path on a GPS isn’t enough.

A truly driverless tractor needs to not only “see”, but to be able to plan a route, interpret the images of the area, and adjust its path on the fly to avoid hazards. For this to be possible, a 3D model of the area around the vehicle must be created, and an algorithm trained to recognize objects at risk of collision.Autonomous vehicles use deep learning algorithms to classify objects around them, and to adjust their paths to avoid them. At the 2019 Agritechnica conference in Hanover, John Deere debuted their concept for an autonomous, single axle, electric tractor.

John Deere single axle autonomous tractor at Agritechnica 2019

While fully autonomous vehicles are still a work in progress, a variety of semi-autonomous vehicles already see widespread commercial use in agriculture in the form of GPS guided tractors, and AI assisted driving.

UAV Monitoring with Machine Vision

Agricultural drone use has become increasingly common over the last several years , and drones equipped with machine vision technology can give growers a big picture view of the health of their crops. Moreover, machine vision technology can “see” and quantify information that the human eye can’t.

Agricultural drones can be equipped with a variety of different sensors and cameras, but all have the same goal of measuring vegetation indices more efficiently than a human on the ground. Vegetation indices are quantitative measures that indicate the health of vegetation based on spectral (light and color) information. Perhaps the best known is the Normalized Difference Vegetation Index. Sometimes described as a “green-ness” and “leafy-ness” index, NDVI calculation uses near infrared waves to determine the coverage and health of vegetation scanned.

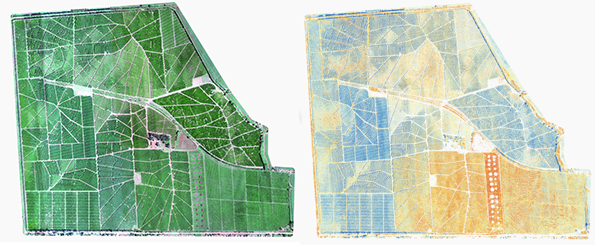

Multispectral cameras are special sensors, used to capture ultra-violet and near infrared light that is typically invisible to the human eye. With multispectral cameras attached to UAVs, growers can create maps that accurately measure chlorophyll levels based on the light refracted. Blue areas of the map have higher chlorophyll levels, while red areas have lower chlorophyll levels.

A standard RGB photo (left) vs the Multispectral image of the same field. Image courtesy of https://www.micasense.com/

Thermal cameras, or thermal infrared cameras, are often used in drone-surveying. Measuring the surface temperature of objects below, a thermal camera equipped drone can create an accurate map of the land surveyed. Thermal infrared (TIR) sensors are popular in nursery management, as subtle changes in temperature can have long term implications for the viability of a seedling. Thermal drone use for irrigation planning is another common application. Studies show that TIR spectrum sensors are extremely effective at measuring water stress in crops - plants experiencing water stress begin to heat up as their pores close and they stop giving off water vapour.

High resolution drone photography can be used not only for crop monitoring, but to accurately count plants, track growth and estimate yield as well. Cape-Town based Aerobotics have developed a proprietary machine learning model that they say will help farmers more accurately estimate yield in citrus fruits. Based on standard growth curves for citrus varieties, the Citrus Yield Estimation system records short videos of sampled trees to identify fruit. The system can then estimate the size, color and number of fruits on the tree. Based on several flights in a season, growers can identify trends in growth and more accurately estimate their yields before harvest.

QA and Grading with Machine Vision

As we mentioned last week, quality assurance and fruit grading is another application of computer vision that requires a high level of detail in order to match the effectiveness of a traditional human operator. Beyond (relatively) simple object detection, quality assurance and grading machines need to be able to identify fruits and vegetables, measure their size and colour, identify defects and diseases, and classify them for sorting. Intelligent sorting algorithms use deep learning to identify and classify fruit, and to spot defects or discrepancies in quality.

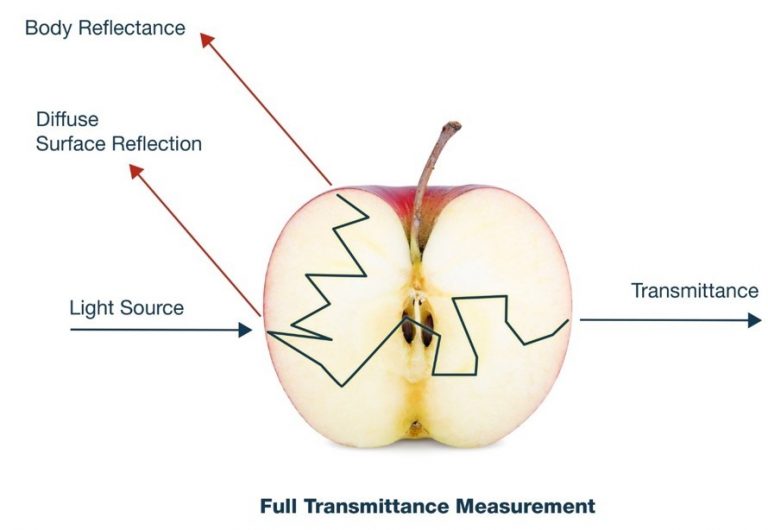

AmazonFresh has been testing computer vision fruit grading technology in their packhouses for several years, and a variety of automated grading and sorting machines already exist on the market. TrueSort™ is a grading technology used in packhouses that uses multispectral and high definition cameras to capture data on size, weight, external defects, and even has an internal quality detection system for apples and onions that uses light shone through a product to assess internal rot, browning, and other internal defects.

TrueSort Full Transmitance Measurement for interior defect detection.

These are just a few examples of how computer vision is reshaping the agtech world, and as research continues we’re sure to see even more unbelievable innovations over the next few years. To find out more about Croptracker’s own computer vision system, check out Harvest Quality Vision, or read more about it in our blog on our public beta.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.

And as always, if you're ever stuck, never hesitate to e-mail us at support@croptracker.com or Live Chat with us by clicking the green speech bubble ![]() in your bottom right-hand corner. We're always happy to help you make the most of Croptracker to make your farm more efficient, safer, and more profitable!

in your bottom right-hand corner. We're always happy to help you make the most of Croptracker to make your farm more efficient, safer, and more profitable!