The Pest Management Regulatory Agency (PMRA) is a branch of Health Canada responsible for the registration, evaluation, and sustainable usage of pesticides. A new update to PMRA policy, “PMRA Guidance Document, Tank Mix Labeling” will go into effect at the end of December 2024, with big implications for Canadian spray operators. In this week’s blog, we will go over the basics of tank mixing, the reasoning behind the process, the current regulations governing it, and the forthcoming changes that will shape future implementation.

Understanding Tank Mixing

Tank mixing refers to the practice of combining multiple chemicals or pesticides into a single tank, which is then used for application over a field or orchard. By mixing various products together, farmers and spray operators can reduce the number of passes required to treat the same area. This method offers increased efficiency, saving time, labor, and resources while maximizing the effectiveness of pest control efforts.

Why Tank Mixing Matters

There are several key reasons why tank mixing has become a popular approach in the agricultural industry:

- Increased Efficiency: By combining multiple pesticides into one tank, farmers can cover large areas in a single application, reducing the time and effort required for multiple treatments.

- Enhanced Weed Control: Tank mixing allows the use of herbicides with different modes of action, making it a valuable tool in combating herbicide resistance. By utilizing various active ingredients, farmers can target multiple weed species simultaneously, minimizing the likelihood of resistant populations emerging.

- Cost Savings: By reducing the number of passes needed over a field, tank mixing helps save on fuel costs, equipment wear and tear, and labor expenses, providing an economical approach to pest management.

What is herbicide resistance?

Herbicide resistance occurs when, as the same herbicide or herbicide groups are applied each year, weeds and undesirable plants begin to adapt and develop a resistance to the herbicide. This development of resistance is an example of a fast-paced evolutionary change through natural selection. As the same herbicide is applied year after year, resistant plants are naturally selected and survive to the next year. The resistant weeds will spread (as weeds do) and eventually, herbicide-resistant plants dominate the whole population. A weed population is defined as resistant when a herbicide loses effectiveness. While there is no explicit standard, a 20% survival rate after application is often used. Herbicide resistance is considered permanent in weeds and their subsequent offspring.

Current Regulations on Tank Mixing

Under the current regulations, tank mixing is permitted unless explicitly prohibited on any of the combined chemical labels. If no prohibitions are stated on the partner labels, currently farmers and spray operators are free to mix the chemicals without any further restrictions.

Upcoming Changes to Tank Mixing Regulations

The PMRA's updated policy on tank mix labeling aims to bring more clarity and consistency to the practice. The new guidelines will require all partner labels to explicitly state that tank mixing is allowed for the combination to be considered acceptable.

While the previous policy relied on the absence of explicit prohibitions, the updated approach will require active confirmation of compatibility from each partner product. This shift places the responsibility on chemical manufacturers and registrants to update their product labels, marketing materials, and extension information to reflect the revised guidelines. The deadline for compliance is set for December 20, 2024.

Implications and Benefits of the Updated Policy

The forthcoming changes to tank mix labeling guidelines carry several important implications:

- Improved Compatibility Assurance: With explicit consent required from all partner product labels, spray operators can have greater confidence in the compatibility and efficacy of the mixed chemicals. This promotes responsible pesticide use and reduces the risk of adverse effects or unpredictable outcomes.

- Enhanced Environmental Protection: The updated policy will help ensure that only compatible combinations are used, minimizing the potential for unintended chemical reactions or negative environmental impacts. By strictly adhering to the approved tank mixes, farmers and spray operators can reduce the risk of contamination and safeguard biodiversity.

- Regulatory Consistency: The new guidelines aim to provide clear and consistent regulations across all chemical products, removing any ambiguity or confusion surrounding tank mix applications. This promotes a level playing field for chemical manufacturers and registrants. It also facilitates ease of compliance for spray operators.

Spray Record Keeping

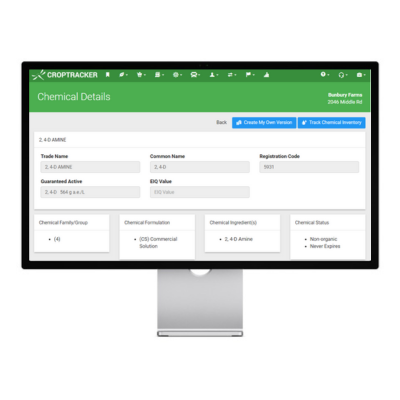

It is also essential for spray operators to maintain accurate records of the tank mix combinations they use. These records should include the names and registration numbers of the chemicals involved, as well as the date and location of the application. This documentation will not only assist in compliance with the new guidelines but also serve as a valuable reference for future use. In Croptracker, users can save chemical information and labels under the chemicals section of the farm manager.

Conclusion

As the PMRA's updated policy on tank mix labeling takes effect in December 2024, Canadian spray operators and individuals involved in pest management must familiarize themselves with the changes. The new guidelines will require explicit consent from all partner product labels, ensuring that only compatible combinations are used. By adhering to these guidelines and staying informed about the specific requirements, spray operators can ensure they are compliant and contribute to sustainable pest management practices in Canada.