Imagine if you had the ability to control exactly how much sun, and rain your crops got. What if you could set the ideal temperature for everything you grow, and could control the humidity and air flow with perfect precision? Grappling with the effects of the environment while producing food has always been the farmer’s biggest challenge. But Vertical Farming takes all the uncertainty out of growing by creating and maintaining the perfect climate for whatever you’re growing.

By growing indoors and controlling all the environmental factors, vertical farms are able to grow all year round, even in urban areas. The indoor farming industry is generating a lot of buzz and is growing fast, with a projected market value of around $3 billion by 2024.

This all sounds like a dream, but is vertical farming really all it’s stacked up to be? In this article we will talk about some of the growing methods used in vertical farming, and the benefits it provides as well as some of the drawbacks and disadvantages impeding the industry.

Vertical Farming is generally used to refer to high-density, indoor operations where crops are grown using climate control. It differs from large scale greenhouse growing in that it requires much less surface area or land and uses artificial lighting, usually high efficiency LEDs, as opposed to sunlight. Plants are typically grown on shelves/in layers using either hydroponics, aeroponics or substrate/soil systems.

In hydroponic growing, a plant is fed using a water and nutrient mix and is not supported in soil. Sometimes the roots of the plants will be suspended in an inert substance like volcanic glass or coconut husk mixtures that retain water and structure to support the plant roots.

Aeroponics is similar to, and often sub-categorized under hydroponics. Plants are fed using water and nutrient mixtures, but it is applied via mist or vapour on the exposed roots of the plant.

Using soil and substrate mixtures for planting is a method well known to any farmer. In vertical farming however, instead of requiring large surface areas exposed to the sun, plants are grown on shelves using high-efficiency LED lights and hydrated using a water recycling system.

A worker inspects a variety of edible flowers at Farm.One in New York.

Vertical farming innovations are being created to address the needs of increasingly urban populations. In the last 40 years, the world has lost a third of its arable land. By the year 2050, over 80% of the world’s population will be living in cities. This population shift is putting more strain on supply chains that need to move food from the fields to the cities.

Demand for fresher products is creating greater a need for food to be produced closer to where people live. Urban farms, like Farm.One, seek to fulfil the needs of restaurants and consumers in their area with fresh greens that do not have to travel across the country or from overseas.

The migration of people into cities has also created an incredible shortage of available labour on farms in rural areas. It is very hard to get people to commute out of cities to work on farms (often for lower wages than jobs in the city). Growing food where people live eliminates this problem. There is a large pool of skilled labour for vertical farms to pull from in the city. The density at which crops are grown on vertical farms also allows for more efficient work-flows, meaning there can be fewer employees compared to traditional farms with similar output rates.

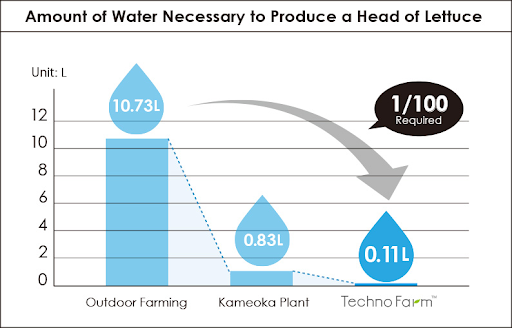

One of the biggest selling points of vertical/indoor farming is the perceived benefit to the environment. On average, vertical farms use 95% less water than open field farming. On the most efficient indoor farms, water is recycled and reused in a nearly closed system. Many indoor farms use existing infrastructure to house their farms, like unused manufacturing facilities, saving resources on building new facilities.

The close proximity to cities also save enormously on fuel, saving both money and contributing less to carbon emissions. Additionally, produce grown indoors needs far less pesticide and disease protection. Many crops are sealed off and hardly handled by humans, protecting them from contamination. This means pesticides and chemicals to manage disease and pests don’t need to be used as often or at all. Many vertical farms grow greens and lettuces because there is a lesser risk of contamination than with field grown and fertilized greens.

Japan's indoor TechnoFarm will use just 0.11L of water to produce a head of lettuce.

Another motivator for developing better indoor farming techniques is the worsening climate and environmental conditions worldwide. As farmland is lost to growing cities, pollution and climate extremes, many companies are developing vertical farming systems to feed growing populations. In Japan, after the 2011 tsunami and nuclear power plant meltdown, much of the country’s farm land was contaminated and unusable. The vertical farming industry in Japan is now one of the largest in the world, home to one of the most profitable indoor farming companies, Spread. Spread’s newest facility, Techno Farms, is so efficient it can grow 30,000 heads of lettuce a day.

A worker at Japan's indoor TechnoFarm in Kyoto tends to a large tray of lettuce.

Not all of Japan’s vertical farming companies are faring as well as Spread, though. 60% of the indoor farms in the country are not turning a profit, and many more rely on government subsidies to operate. This problem of profitability with indoor farming is not limited to Japan. In many places the costs of vertical farming make the produce extremely expensive.

Real estate prices within cities are significantly higher than land in rural areas making the upfront investment and continuing property taxes too high. The utility rates within cities can also be prohibitive. The operating costs for the extensive lighting and climate control systems necessary to vertical farming are huge. There are extra labour costs with indoor farming as well due to the nature of growing inside. All pollination needs to be done manually.

Additionally, long term cost saving solutions, like robotic pickers and pollinators, are often too expensive to be implemented. And while being in total control over the environment your plants are grown in is great, it also means vertical farms are entirely dependent on technology that could fail. Power outages or software crashes could have catastrophic consequences.

It is also important to note that long term studies on the environmental impact and efficiency of vertical farming have yet to be released. Some farmers and experts believe it is still more useful to build horizontal green houses as opposed to vertical and artificially lit operations. Louis Albright, a controlled climate farming expert from Cornell University, proposes that a better solution for creating more local food would be to build green houses just outside of urban areas.

Controlling and adapting to environmental factors is an ongoing problem for growers, but is vertical farming the solution? In order for vertical farms to stay manageable, and to become profitable, companies will need to continue to experiment, innovate, and analyze every aspect of their processes. Data management will play a huge role in refining vertical farming practices. Production practices, material, electricity and water use, and labour expenses, are all factors that will need to be measured and assessed to determine the best processes for a new style of farming. Farm management software helps growers to keep accurate records, enhance traceability and food safety, and to store and analyze data from every aspect of your operation. Vertical farming has yet to prove itself in the market but the possibilities and innovations it provides will push agriculture technologies toward the future.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.

And as always, if you're ever stuck, never hesitate to e-mail us at support@croptracker.com or Live Chat with us by clicking the green speech bubble ![]() in your bottom right-hand corner. We're always happy to help, so Croptracker can make your farm more efficient, safer, and more profitable!

in your bottom right-hand corner. We're always happy to help, so Croptracker can make your farm more efficient, safer, and more profitable!