Firmness is widely recognized as one of the most essential quality metrics in the fresh produce supply chain, acting as a universal index for gauging maturity, optimizing harvest timing, and predicting shelf-life potential. The physical structure of a fruit or vegetable determines its ability to withstand handling, storage, and transport, directly influencing its final value.

Mirroring the wider trends in agricultural technology, the processes governing firmness testing are rapidly evolving from purely mechanical methods to digital systems that offer automated readings, data logging, and seamless connectivity via USB or Bluetooth. This technical round-up reviews some of the most popular technologies used for measuring firmness in fresh produce. We have divided the tools into two main categories: Destructive testing and Non-destructive testing.

Firmness and pressure testing tools defined

For this tech round up, we have defined the tools for testing pressure into two main categories. We have focused on mechanical based testers and have not included light or radiation based testing tools in this round up.

Destructive testing (Penetration)

The traditional method, primarily executed using penetrometers, involves the application of pressure via a probe, or plunger, of a standardized diameter into the fruit flesh. It measures the force required to puncture the fruit's flesh. For larger fruits (like apples and peaches), the skin is first removed, and the measurement captures the Peak Force required for the probe to penetrate the flesh to a specific, standardized depth. This group includes both operator-dependent Handheld Penetrometers and high-precision Automated Penetrometers (ATAs).

Handheld Penetrometers

Handheld penetrometers are the most common tools for post-harvest assessment, providing a straightforward measurement of flesh resistance via manual penetration.

Analog Penetrometers

Analog testers utilize a mechanical spring mechanism to gauge resistance, featuring a peak-hold needle that physically freezes the dial at the maximum force achieved during penetration. They are cost effective and rugged for on the go and frequent use.

Digital Penetrometers

Digital penetrometers replace the mechanical spring with an electronic load cell, resulting in a direct digital readout and higher intrinsic accuracy (±0.5%). Many of these tools are preferred for precision and data transfer as some models support bluetooth or USB data transfer.

Automated Penetrometers (ATAs)

Automated Penetrometers, or Automated Texture Analyzers (ATAs) represent the highest tier of firmness testing. They are the mechanical evolution of the penetrometer, engineered specifically to eliminate operator error, making them essential for high-throughput industrial operations and post-harvest research. ATAs entirely eliminate the subjective variability introduced by human operators. They achieve this by utilizing motorized systems to precisely control critical parameters: the speed of the probe’s travel (typically 1 to 40 mm/sec) and the exact depth of penetration. This standardized, mechanical control ensures highly accurate and repeatable results, a requirement for stringent research applications.

Measurement units for destructive testers

Readings are standardized force measurements, typically reported in Kilograms kg, or Pounds lb. These instruments often calculate the force applied per unit area, resulting in derived units such as kg/cm2 or lbs/in2. Automated Texture Analyzers (ATAs) tend to use Newtons N or grams g for high precision, but often offer scale display conversions.

Non-Destructive Testing (Deformation / Compression)

Non-destructive testing is preferred for soft, high-value fruits and when maintaining inventory integrity is paramount. It measures surface compression or depression without physically damaging the fruit. This group includes specialized Handheld Durometers and configurable Automated Lab Deformation instruments.

Both these tools measure the force required to compress or deform the surface of the intact fruit by a minute, predefined distance, often around 1 mm for small fruit. By keeping the skin present and limiting the depth of contact, it effectively preserves the fruit's cosmetic and physical integrity.

Handheld Durometers

These portable instruments are designed for field and packing house use where sample preservation is paramount, providing critical QC data while minimizing economic loss. They often have digital display screens, but analog models are available.

Automated Lab Deformation instruments

This tier includes automated systems that are primarily configurable for non-destructive measurements, offering the highest level of repeatability for soft fruit analysis in a laboratory setting.

Measurement units for non-destruction testers:

The Durofel scale is a specialized, non-destructive, empirical scale ranging from 0 to 100 units, specifically utilized for assessing the firmness of extremely sensitive commodities such as tomatoes, cherries, strawberries, and soft berries. The Durofel principle measures surface depression caused by a calibrated force.

Tools like the HPE III - Fff Non-Destructive Digital Penetrometer measure firmness using an empirical scale of 0–100 Fff units (where Fff stands for Fruit Firmness), suitable for non-destructive hardness testing of a variety of produce.

Both the Durofel and Fruit Firmness scales are based on the ‘Shore Hardness Scale’ developed to measure the firmness of substances on a scale from 0 resistance (air) to 100 (glass hardness).

Tester tech comparison table

This table provides a critical side-by-side comparison of the leading commercial models across for pressure testing, including all testing tools

| Make / models | Category | Features | Scale | Data display / transfer | Price USD |

|---|---|---|---|---|---|

| QA Supply handheld model penetrometers *similar models to Turoni version below  |

Analog penetrometer | - Various sized models to support multiple crops - Warranty and calibration certifications available with purchase - Options to pair handheld model with a stand for increased precision and accuracy |

Force - kg & lb | - Analog display - No data transfer |

~$260.00 |

| Turoni fruit penetrometers *similar models to Turoni version above  |

Analog penetrometer | - Various sized models to support multiple crops - Includes multiple tips per model - Options to pair handheld model with a stand for increased precision and accuracy |

Force - kg & lb | - Analog display - Supports data transfer |

Unlisted - contact manufacturer for a quote |

QA Supply or Turoni handheld digital penetrometers  |

Digital penetrometer | - Includes multiple tips to support testing on large and small fruit - Options to pair handheld model with a stand for increased precision and accuracy - Easy to toggle between kg/lb scales and increase display brightness for in sunlight use |

Force - kg & lb | - Digital display - USB data transfer |

~$500.00 |

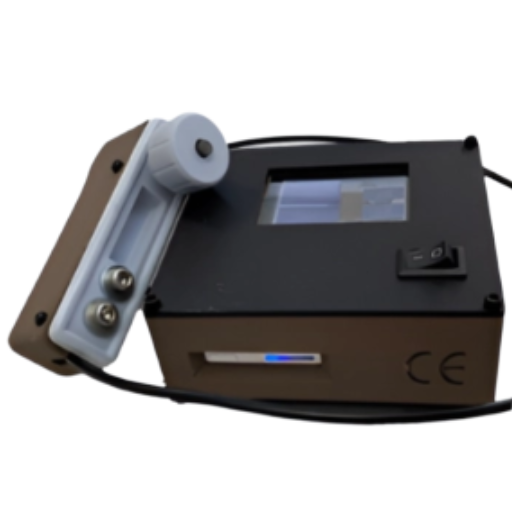

Guss Fruit Texture Analyzer  |

Automated penetrometer | - Data connected to computer and is formatted in spreadsheet and graph displays - Can be paired with a scale to weight sampled fruit at the same time - Increased accuracy over handheld/manual testing due to standardized speed and force |

Force - kg & lb | - Connected to a computer for displayed results - Displays results from multiple samples concurrently |

~$5250.00 |

Turoni hardness testers  |

Handheld durometer | - Digital data display which prompts for sampling on both sides of the fruit to return one number per sample - Comes with carrying case and in various tip and depths to support various small fruit sampling |

Shore - 0-90 scale | - Digital display - No data transfer |

Unlisted - contact for a quote |

Bareiss fruit firmness tester HPE III Fff series |

Handheld durometer | - Highly accuracy handheld device - Features audible tone to indicate a successful reading - High IP rating - Large internal memory to support 300 readings before data transfer - Options to pair handheld model with a stand for increased precision and accuracy |

Fff - Fruit firmness 0-100 | - Digital display - USB data transfer - Complimentary software for analysis |

Unlisted -contact for a quote |

Agrosta 100 Field Digital Firmness Tester |

Handheld durometer (digital) | - Different sensor options available calibrated to support specific crops - Features large screen digital display for easy reading in the field - Precision measurements - Supports batch measurements |

Durofel -0-100 with 1 resolution | - Digital display - Bluetooth data transfer - MicoSD data storage and transfer |

Unlisted - contact for a quote |

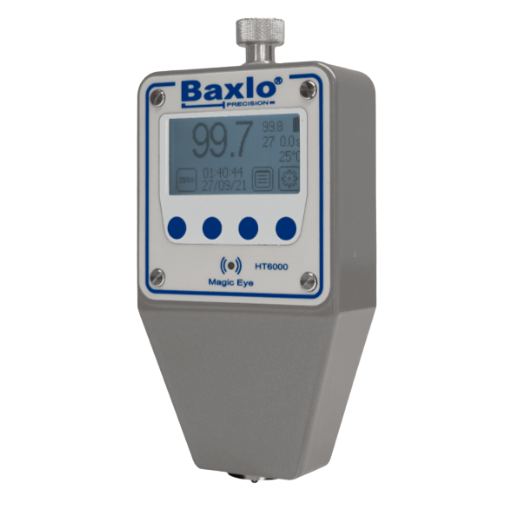

Baxlo Baxlo Digital Fruit Firmness Testers  |

Handheld durometer (analog) | - Different models available calibrated to support specific crops - Precision measurements - Support batch grouped measurements - Rechargeable battery with 150hr run time |

Shore -0-100 with 0.1 resolution | - Digital display - USB data transfer |

Unlisted - contact for a quote |

Baxlo Analog Fruit Firmness Testers  |

Handheld durometer (analog) | - Different models available calibrated to support specific crops - No battery required |

Shore -0-100 with 1 resolution | - Analog display - No data transfer |

Unlisted - contact for a quote |

| Fruit Quality FirmTech firmness measurement instruments FirmTech FT7 FirmTech 11  |

Automated lab deformation instrument and penetrometer | - Automated table top system for loading and automatically testing multiple samples in batch - Connected software for reporting and data organization - High speed and highly accurate sampling - Support penetrometer and durometer testing for small and large fruit - Returns fruit size in mm as well as firmness measure - Exchangeable turntables and configurations to support different crop types |

Force - g or kg | - Connected computer display with companion software | Unlisted - contact for a quote |

Firmness remains the universal index of quality in fresh produce, and the technology to measure it is rapidly evolving. This review shows a clear industry move away from highly operator-dependent methods towards digital, automated systems that enhance accuracy and traceability.

The key distinction lies between:

- Destructive Penetration: Ideal for harder fruits, utilizing Handheld and Automated Penetrometers (ATAs) to measure the force required to puncture the flesh with high precision.

- Non-Destructive Deformation: Essential for soft, high-value produce, relying on Durometers and Automated Lab Instruments to provide surface readings via empirical scales (like Durofel), preserving the fruit's integrity.

As supply chains demand objective data and minimal waste, the future lies in instruments with electronic load cells, data logging, and automated control over the testing process. By choosing the appropriate destructive or non-destructive tool, the industry can meet the rising consumer expectation for consistent, high-quality fruit