This piece is a part of our ongoing agtech feature series, highlighting bright innovations impacting the agricultural sector.

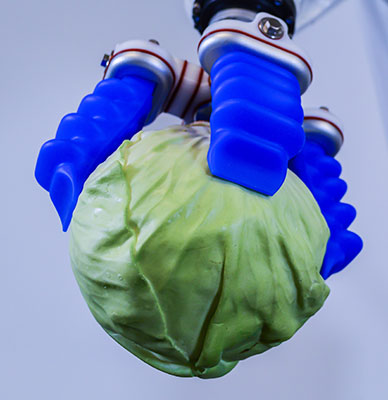

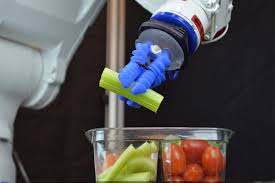

Soft Robotics’ gripper technology offers a non-traditional robotic approach to picking up objects with tact and versatility, closing a major use case gap for automation in manufacturing. By creating an end-of-arm-tool (EOAT) that can reliably pick and place objects without damage or chaos, high-speed automation can now be a viable replacement to human workers’ movements.

The company’s innovative contributions to robotic automation have greatly impacted manufacturing, particularly with applications in picking and packing for consumer goods, like fresh produce and other food products. As the need to protect laborers working in close proximity remains heightened amidst the COVID-19 pandemic, robotic solutions like Soft Robotics’ that can stand in for (and improve upon) the human touch are more in demand than ever.

Biomimicry in scientific innovation

The movement of an octopus is the inspiration for Soft Robotics’ “hand” technology, embracing the concept of biomimicry within the award-winning polymer science developed in Harvard University’s chemistry department. Biomimicry looks to existing natural structures for technological innovation. This is opposed to framing research around an assumption that new strategies and technologies must be forged in a vacuum of human imagination. Emulating what already exists (and works) in the world, biomimicry promotes design that prioritizes circularity, sustainability, and regeneration.

Soft Robotics’ mGrip grippers

The mGrip Ecosystem can be used with every major robotic arm product on the market, with a modular design that’s programmable through its associated Control Unit. The mGrip is an EOAT with an enveloping grasp, allowing a robotic arm to effectively pick up bagged, unstructured, and delicate items. The soft robotic fingers of the gripper wrap around the object, avoiding the pitfalls of vacuum suction tools

The biggest barrier to adopting robotic tools in the food sector is efficient sanitary maintenance practices and food safety. The mGrip is designed for use on food lines, and as such is compliant with major food safety regulations like EC1935 and FDA CFR Title 21. By running on a closed pneumatic system, the mGrip Ecosystem will not be internally contaminated by food particles in the way that vacuum handling solutions must navigate. Vacuum handling is an open system structure that requires a filtration method for capturing debris internally – this adds another point of cleaning labor, and greater risk of harmful bacteria growth or cross-contamination of allergens. The mGrip has only exterior components coming into contact with food on the line, and so there’s full ingress protection for cleaning in place.

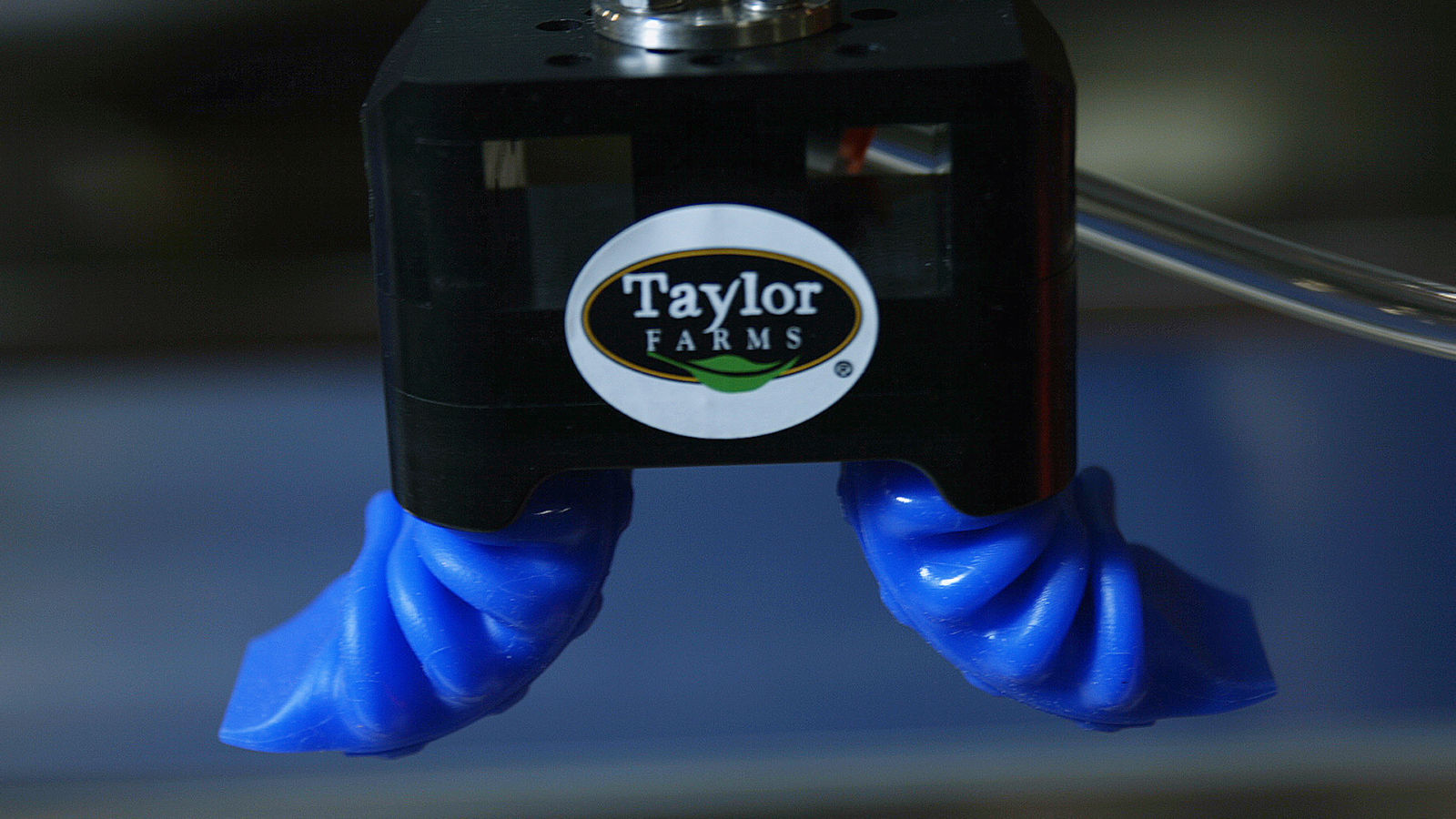

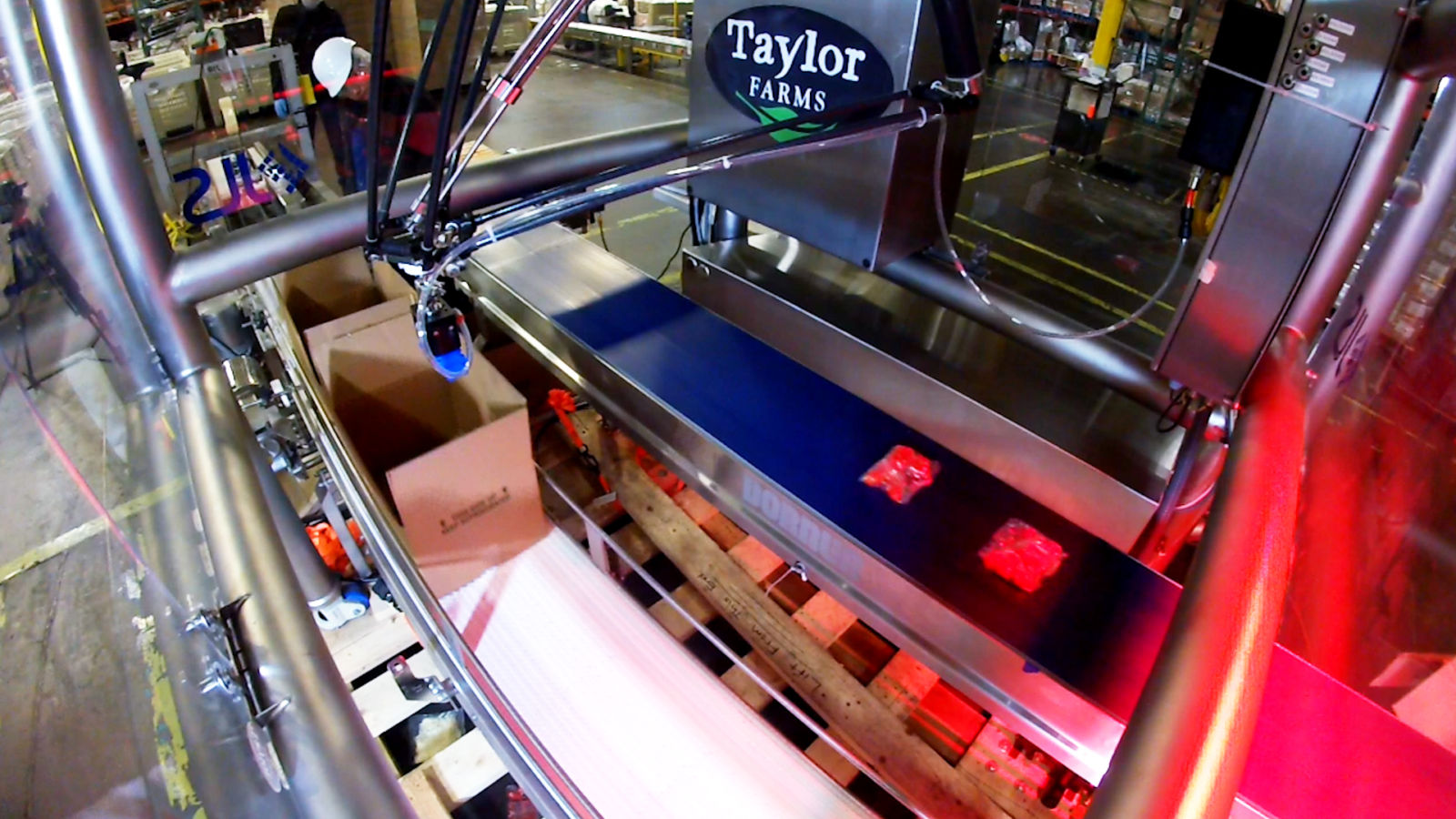

Grippers in action: Taylor Farms Case Study

Taylor Farms makes prepared salads, snack trays and other fresh produce-based products that equate to a lot of repetitive and physically demanding work. Soft Robotics’ solutions are modular, so its automation system can be retooled and reprogrammed for short product lifecycles. With new practices launched in 2016, packing for products like bagged salad is now exponentially faster, with 60-80 bags packed per minute. This technological shift in food packing and processing allows for better paying jobs on the floor that are less physically demanding.

Navigating the needs of a particular client’s workflow can involve some trial and error. When robotic arms and grippers were initially implemented at Taylor Farm’s, the system wasn't capable of handling the very wet environment required for maintaining sanitation standards. Since the arms include no mechanical or electronic parts, the Soft Robotics team was quickly able to iterate and adapt to its client’s conditions.

Innovative technology applications are a must for staying on top in a sector with ongoing labor and safety challenges. From robotic solutions like those from Soft Robotics to predictive scanning tools like Croptracker’s Harvest Quality Vision, exploring new directions for a successful season is in your best interest.