Accurate classification is the key to quality assurance and integral to success in commercial-scale produce markets. Apart from filtering out obvious disease, size is a primary classifier for selling fruit in graded classes. When it comes to sizing fruits like apples and peaches, the tried and true methods are still a big part of the production process. Contemporary tech solutions compliment the human touch while speeding up the processing element of harvest. Having the right tools in your toolkit improves your competitive advantage in the highly time-sensitive world of perishable goods.

Grading classes

Fruit grades correlate to the larger marketplace grading standards that frame the value and sale to manufacturers and grocers. These parameters are formed by interrelated criteria defined internationally, regionally, as well as internally to growers. Using apples as an example, U.S. Grade Standards No. 1 and No. 2 are relatively differ in the percentage allowance of defects per apple that might end up being removed as waste when utilizing. U.S. No. 1 permits five percent or less defect, and U.S. No. 2 permits twelve percent or less. These grades do not encompass size criteria – this specification is determined between the grower and the seller.

This is where internal grading standards come into play. Market demand directs color and size grading, as well as how it correlates to its market value. Top apple grades are associated with the most appealing and precise hue and size ranges, and lower grades allow for greater variability. The value of the commodity typically decreases as the color profile wanes and size decreases. The sooner that the specifications of the fruit can be anticipated and verified, the faster this information can be communicated to marketers who can secure the crop’s sale.

Traditional methods of size grading

The standard way to grade fruit for sorting and preparing for distribution is shifting toward the more technically complex, but the original QA tools remain for their simplicity, portability and cost-effective accuracy.

Ring sizers: Grouped together as a set or available individually, fruit ring sizers are great for size quality checking a wide variety of consistently shaped round fruit, from apples and peaches to citrus like oranges.

Benefits: durable materials, reusable, suitable for quick “yes/no” size categorization, affordable enough for stocking many for your operations

Drawbacks: fixed sizes limit capacity for precise measurement, may need different sets for different commodities

Sizing bands and gauges: These tools can be simple, standalone bands with diameter measurements indicated, or an adjustable band loop attached to a handle, allowing for one-handed measurements like the one found at QA Supplies.

Benefits: Great for sorting or quality inspections, portable, affordable, reusable, suitable for quick checking or a more precise diameter measurement done by Hand.

Drawbacks: Size range limitations, time consuming to hand measure with if requiring precision.

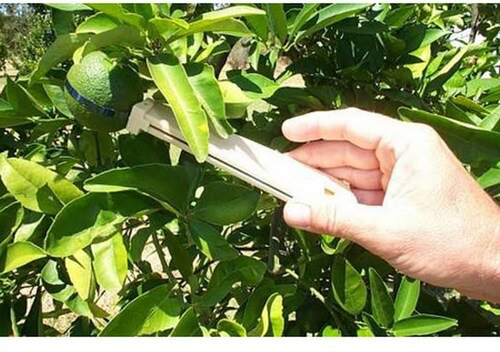

Calipers: Designed specifically for versatile diameter measurement, calipers like the ones above for analyzing citrus, are USDA approved for inspection tools. Some varieties are available for specific fruits, but you can find generic ones out there, as well.

Benefits: Regulatory-body approval of tool, high accuracy, portable, durable, fast adjustment.

Drawbacks: Adjustment requiring two hands, size range limitations.

Electronic Fruit Sizer and Data Logger: Take the documentation step out of the process with an electronic fruit measurer (EFM) . A hand held device with a sensor tape similar to a sizing band, an EFM can measure the full diameter of fruit on the tree, while the readings are captured on the device. When you’re ready to process the data, bulk export the information onto your computer system. Store up to 12,000 entries.

Benefits: Efficient data logging, high accuracy measurement on site, digitized raw data.

Drawbacks: High cost per unit compared to other hand tools, greater need to protect device from elements

Classifying with new and emerging tools

Harvest, sort, pack – there’s no time to waste once fruit is grown to maturity. Likewise there’s always room to better refine the workflow, and investing in new technologies might be the right way forward for your operation.

Optical packline technology

If you’re operating a large packing house, you likely have some type of mechanized packline or sorter involved in your process. Once the fruit has been harvested, save an immense amount of time sorting and grading with an optical packline solution that promotes consistency in packouts and detects defective fruit better than what is possible with the human touch.

Compac: A leader in packhouse technology, Compac offers turn-key packline products specific to a commodity type. Its optical systems size produce by measuring multiple diameters and comparing these digital images to ensure the highest possible accuracy. With the ability to detect and plot the equatorial and shoulder diameters of fruit like apples using the stem detection feature, produce can better fit into packaging. Irregularities can be easily filtered out. This comprehensive system offers a lot of pay off, however the commitment to investment remains high, with upfront costs to adopt and procedures to implement across packhouse staff.

Harvest Quality Vision (HQV) technology: Harvest Quality Vision technology offers comparable size scanning functionality to an optical packline, with the major advantage of mobility. Scan for size right in the orchard row, or over a bin sample off the truck before processing. This way you can refine what is selected for picking as harvesting is under way, saving time and labor in the pre-sorting process. Scanning sample bins also assists with storage organization – the size classing begins before the fruit enters the sorter. HQV is a quality assurance tool that can complement your existing packhouse infrastructure with optical tech that doesn’t break the bank.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.

And as always, if you're ever stuck, never hesitate to e-mail us at support@croptracker.com or Live Chat with us by clicking the green speech bubble ![]() in your bottom right-hand corner. We're always happy to help you make the most of Croptracker to make your farm more efficient, safer, and more profitable!

in your bottom right-hand corner. We're always happy to help you make the most of Croptracker to make your farm more efficient, safer, and more profitable!