Timing is critical in the farming industry, and harvest is no exception. In the apple industry, where product may be held in controlled atmosphere (CA) storage for long periods of time, determining the ideal harvest window is even more essential to guaranteed longterm quality.

Timing a harvest to ensure that apples are picked at the right time for taste and quality is a much simpler process if fruit are going to sale immediately, but significantly more difficult for fruit destined for longterm or CA storage. Harvesting apples too early can result in hard, acidic fruit that are more likely to develop issues like scald and bitter pit during storage. On the other hand, harvesting too late can result in shorter shelf life, a soft, grainy texture, and easily bruised fruit that loses its shine and appears dull. Late harvesting also increases the risk of apples dropping from the tree on their own.

With a harvest window as short as just seven days, organizing in advance, scheduling bin drops, preparing storage, and ensuring that sufficient labor is available are critical. So how do growers determine when to start harvesting?

The starch-iodine test is one of the main preharvest tests apple growers use to determine the ideal harvest window. A Starch Pattern Index (SPI) is a visual tool used to estimate the starch levels in the fruit using an iodine solution. To determine the ideal window, testing for starch levels should begin at least four weeks before the expected harvest date, and additional tests should be done at least once each week until the optimum harvest window is determined.

Why Starch?

Starch is a type of carbohydrate that is found in many plants, including fruits such as apples. In unripe apples, starch is the primary form of carbohydrate present, but as the fruit ripens, the starch is converted to sugar. The amount of starch present in an apple is one metric used to determine its level of ripeness, with more starch indicating that the fruit is less ripe.

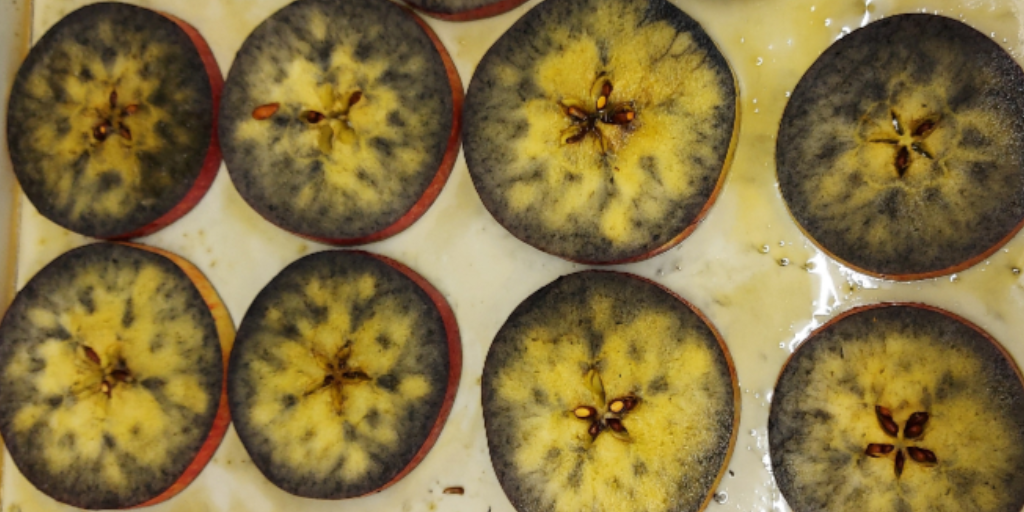

The starch test used in apple harvesting is based on the principle that iodine reacts with starch to produce a blue-black color. By applying an iodine solution to a cut surface of an apple, the amount of starch present can be determined by the intensity of the color produced. Different apple varieties may require different levels of staining to indicate the appropriate level of ripeness, so it is important to use the appropriate chart for each variety.

While there are other methods for measuring ripeness, such as measuring ethylene (sometimes called “the fruit ripening hormone”), the starch test is preferred for apple harvesting due to its relative simplicity and cost-effectiveness. Ethylene measurements require expensive specialized equipment which is typically only available in labs, but starch testing can even be performed out in the field. Preparation for starch testing is also relatively simple; it is possible to make an iodine solution at home. One method is to simply purchase a 2% alcoholic solution of medicinal iodine at a drug store and mix it in a 1:1 ration with water. Another method, more suitable for starch testing in large quantities, involves adding potassium iodide and iodine crystals to distilled water and allowing the solution to sit overnight to fully dissolve the iodine.

The Methodology:

A simple starch test can be performed by anyone! (In fact the iodine starch test using an apple and a potato is a popular lab experiment in elementary school science classes!) The main challenge in starch testing lies in the interpretation of results.

- Select ten trees from different areas of the block and tag them for identification purposes.

- Take one or two apples from different sides of each tree. Choose the most average-looking sample from the outside of the tree rather than the inner shaded area.

- Cut the apple in half at the equatorial line (Test the apples within 24 hours of collection to obtain accurate results).

- Apply the iodine stain to the cut surface of the apple. This can be done using a brush, by dipping the apples into the stain, or with a spray bottle.

- Wait for at least one minute to allow the iodine to react with the starch in the apple tissue.

- Arrange the apples in order of stain percentage by visually comparing the amount of iodine staining on each apple.

- Use the chart for interpreting iodine staining for comparison to determine the starch level of each apple.

- Record the starch level. The less starch, the less iodine development there will be, so the darker the apple the less ripe it is.

- Compare the starch levels for the variety to the corresponding chart to determine the ideal harvest window for the apples.

SPI Scoring Systems:

While the testing process remains the same across the board, there are several scales used around the world to assess the results.

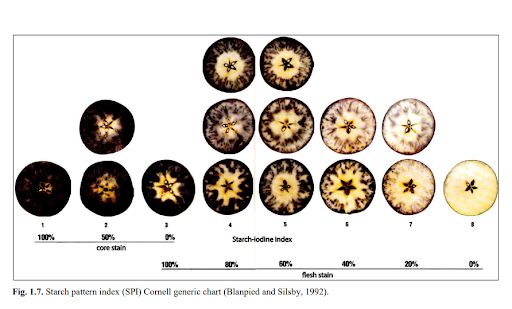

Cornell starch-iodine index

The Cornell starch-iodine test is scored out of 8 with one being the darkest stain, and therefore most starchy and least ripe, and eight representing the lightest, most ripe apples. This chart is generic across varieties. Some recent studies suggest that this method is less effective in determining true long term storage potential as it is based on tests done after only three months in storage.

Centre Technique Interprofessionnel des Fruits et Lėgumes (CTIFL)

The CTIFL scale was developed in France with particular emphasis on European cultivars specifically. This chart uses the classic 10-stage scale and is popular in Europe.

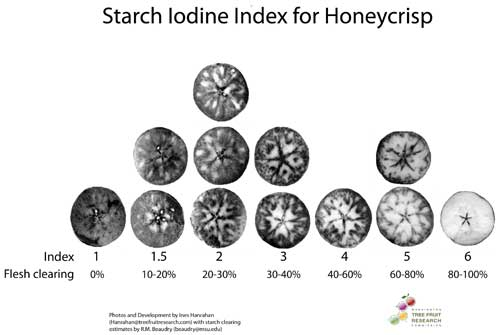

The Honeycrisp Problem

The ever popular Honeycrisp apple is a sensitive cultivar with very specific storage requirements. The Washington State Treefruit Research Commision has created a specific starch index for these finicky apples, which stain in patterns inconsistent with the other varieties and starch scales.

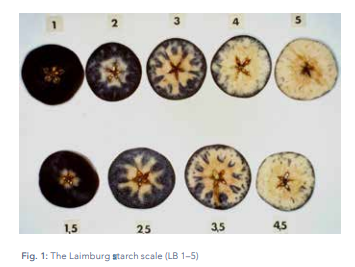

Laimburg scale

The Laimburg scale is a 1.0 - 5.0 ranking to one decimal place used most commonly in European regions around Germany, Austria and Italy. This score is often converted to a ten point scale after grading for use in the Streif Index Method.

The Streif Index:

Not strictly speaking an SPI, the Streif index is calculated from the results of three quality control tests; a starch test, pressure test, and a test of soluble solids concentration, or Brix. The Streif Index is meant to be a more thorough and accurate measure of maturity than using starch alone.

Calculating the Streif Coefficient

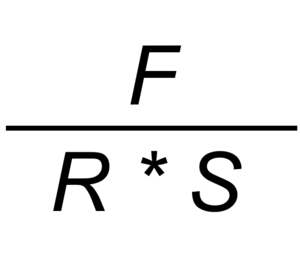

The equation F/(SSC x S) where F = Flesh firmness, SSC = Soluble Solids Concentration and S = Starch test results provides the Streif coefficient, which is then compared to the ideal values of individual varieties and regions.

Lower values mean the fruit is closer to maturity, and the Streif Index is particularly valuable not just as a tool to determine the start of harvest, but to determine the last possible date.

Subjectivity in Assessment

What all of these methods have in common is the most challenging aspect of starch testing: these tests all rely on a human assessment of the staining level, and a consistent assessment is key. Two technicians looking at the same starch test may give different results, and human perception is notoriously subjective. In many cases, organizations will have a single person dedicated to assessing all of their starch tests to try to reduce inconsistency in their assessments. But the human eye is strongly influenced by comparison: looking at a tray of tests with a high stain value will often affect the grade of the next tray. After all, it’s much lighter than the last tray! That’s why apple growers around the world are seeking advanced digital solutions to score their starch tests. While nothing is commercially available yet, this technology is certainly in the works, and the idea of AI starch test scoring is gaining traction in the agtech world.

Croptracker creates advanced solutions to complex industry problems. Our goal? To help you replicate your success with the same confidence, every time.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.