Computer vision may seem simple enough to understand, but below the surface, it is a complex and multidisciplinary field, tied up with a variety of technologies, both old and emerging.

What is Computer Vision?

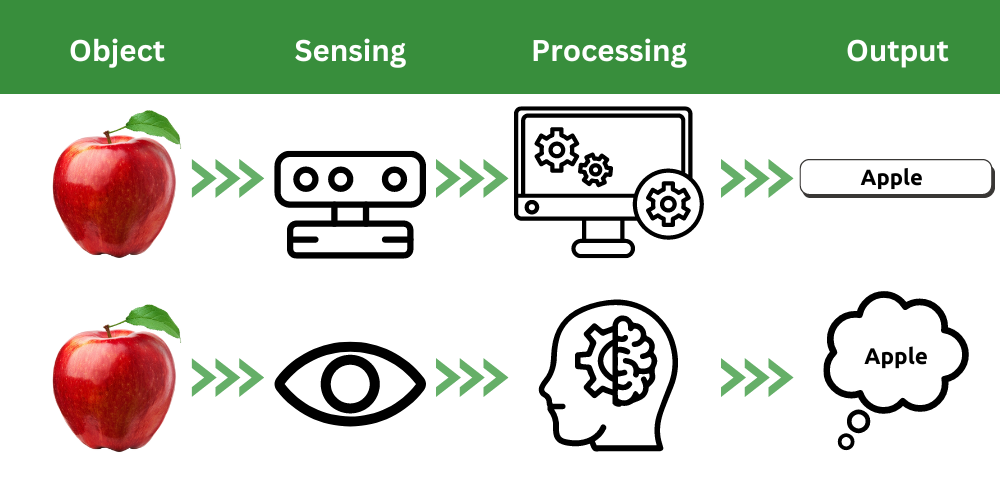

Computer vision may use a variety of cameras to act as the machine’s “eyes” depending on the imaging requirements. Infrared, multispectral, thermal or even three-dimensional cameras can be used to process depth and size and provide orientation details about detected objects. The process is usually compared to human perception in a diagram like this:

For agricultural applications, merely detecting a preset object just isn’t enough - produce is rarely uniform and may vary in size and color, and more processing is needed to actually identify the fruit. In short, the “seeing” aspect of computer vision is only the beginning, identifying or understanding the image is the next step.

This “understanding” of an image is a significantly more complicated affair, and the training processes are typically segmented into either machine learning or deep learning. In layman’s terms, machine learning is an algorithm-based system, that parses data, learns from it, and applies that data to future decisions or recommendations. Applications like Spotify use simple machine learning of this type to analyze your music tastes and make recommendations. Your liked songs act as structured data for the algorithm, which then finds similar songs to recommend to you.

But no matter how many analogies a tech blogger may make, a computer is not a brain and cameras are not eyes. So what is ACTUALLY happening when a computer “sees” something? Setting aside the issue of eyes or hardware, there are a few processes occurring in the background between collecting the image and the result. Vision is in fact a bit of a misleading umbrella term for a variety of processes. Some of the most common “types” of computer vision are:

Classification:

Object recognition or image classification, refers to the process of identifying an object in an image or video. Recognition is typically the first step in any computer vision program. Object recognition algorithms are typically trained to recognize specific features of a detected object to identify it.

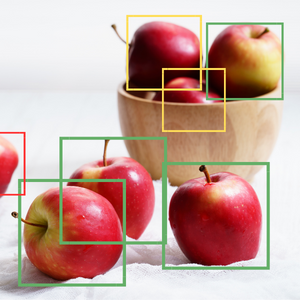

For instance, an object recognition system may look at an image like this and identify that there is an apple present in the scene. To accomplish this, the system is trained on images of apples to teach it what characteristics and attributes to look for in a scene to find an apple. Typically, computer vision systems will also include a confidence rating, which represents how sure the system is that what it is seeing is in fact an apple. That’s as far as object recognition goes though, the image contains an apple. The system doesn’t know where in the image it is and doesn’t count the apples, but an apple has been positively identified in the frame.

Object detection

Object detection not only identifies the presence of an object but detects multiple instances of the object class. In object detection, the system identifies the approximate location of the instances in the scene within a bounding box.

Image segmentation

In segmentation, the system not only identifies the instances of apples and their locations but specifically categorizes which pixels of the image represent each instance. Rather than using a bounding box, image segmentation creates a pixel-level mask of each instance.

Computer Vision In Agtech

Efficient and accurate machine vision remains one of the biggest challenges in agricultural AI, especially for use in the unpredictable outdoor conditions of a field or orchard. Unpredictable lighting, inconsistent shapes, obstruction by foliage or other fruit, all these factors and more make in-tree detection a complicated affair.

Weeding with Machine Vision

Combating weeds and making sure crops have room to grow is a constant struggle for farmers. Weeds pose a considerable challenge for growers, as they compete with crops for vital resources such as soil nutrition and water, occupy valuable space in fields, and limit the growth potential of desired crops. The Carbon Robotics LaserWeeder™ is an autonomous weeding system that relies on the power of computer vision to deliver chemical-free and no-till weed control. Equipped with multiple tracking cameras, it can accurately identify and target weeds, following along furrows in fields to navigate without the use of a GPS! By leveraging this cutting-edge computer vision technology, the LaserWeeder™ ensures efficient and effective weed management, leaving crops unharmed while eliminating the need for chemical application.

Harvesting with Machine Vision

Automatic harvesting brings additional challenges to the table, with various hardware requirements for grabbing delicate produce without damaging it. Innovations in so-called “soft” harvesting, where machines are equipped with delicate suction cups or padded grabbers are just one way growers are protecting their produce during autonomous harvests.

At Mycionics Inc here in Ontario, they’re bringing the benefits of AI harvesting to the mushroom industry. Mycionics’ fully automated mushroom harvesting system picks, packs, cuts, and weighs mushrooms based on grower specifications. Their patented touch-sensitive gripper technology picks faster than a human harvester, without damaging or marking the delicate mushroom caps it handles.

QA/Grading with Machine Vision

Quality assurance and fruit grading may need even more detailed computer vision technology to match the effectiveness of a human operator. Beyond fruit detection, quality assurance programs may measure size, color profile, ripeness, and detect defects, identify diseases, and classify scanned fruit based on these metrics.

Technologies that can reduce the need to presort fruit are always in demand; in cases where presorting is impossible, systems that can provide any additional information on harvested inventory can be a game changer when it comes to storage efficiency. Croptracker’s Harvest Quality Vision collects data on scanned fruit to assess size and color. Using this data, growers can more intelligently group their lots, storing like fruit together and maintaining more up-to-date information on the quality of stored fruit. Harvest Quality Vision prepares your packline, storage, sales teams, in just minutes, with information about the average size of the fruit, the size band this bin most closely fits into, the color data, and QC and traceability information all attached, with just an iPad.

Computer vision is a powerful technology that enables machines to "see" and interpret visual information much like humans do. Despite its progress, computer vision still faces challenges in handling outdoor conditions, inconsistent shapes, and obstructed views. However, advancements in hardware, algorithms, and deep learning techniques continue to push the boundaries of computer vision in agtech. As computer vision continues to evolve, its integration with other technologies such as robotics, machine learning, and artificial intelligence holds tremendous potential for revolutionizing agriculture. The ability to accurately perceive and understand visual data opens up opportunities for increased efficiency, improved productivity, and enhanced decision-making in the agricultural sector. With ongoing research and development, computer vision will continue to shape the future of agtech, transforming the way we cultivate, manage, and optimize crop production.

Croptracker develops agtech solutions for industry leaders. Located in Eastern Ontario, Canada, our mission is to make crop production safer, more efficient, and more profitable. Designed in partnership with fresh market producers and distributors, every tool we create is based on direct industry feedback.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.